Please login to use this feature.

You can use this feature to add the product to your favourite list.

Close

You have removed this product from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your favourites list.

Close

This company has been removed from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your inquiry cart.

Close

This company has been added to your inquiry cart.

Close

This company has been removed from your inquiry cart.

Close

This product has been added to your inquiry cart.

Close

This product has been removed from your inquiry cart.

Close

Maximum number of Product/Company has been reached in inquiry cart.

Close

You have removed this product from your favourite list.

Close

Daily Login Reward

Congratulations!

You��ve earned your daily login reward for today!

5 NP PointHere are the reward you��ve earned!

Check your Daily Login Rewards

Be sure to come back everyday for more rewards!

Thanks!

Scan and Whatsapp Me

![qr code]() Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Waktu

Pejabat

Isnin - Jumaat 9:00 AM - 5:00 AM

Sabtu - Ahad Closed

We′re closed on

Public Holiday

Get the latest

VG Instruments (SEA) Sdn Bhd

App for Android

Open

Closed

Selangor,Kuala Lumpur (KL),Kepong - Point level detection in a heat exchanger

12-Dec-2018

Point level detection in a heat exchanger

Process data

Application

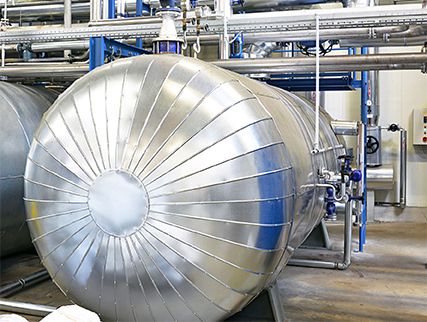

Heat exchanger in a power plant

Application

A large power plant needed a redundant overfill protection system for four of its boilers. Planning and implementation of the project were carried out by the engineering firm Wolter & Dros B.V. The heat exchangers, which were already equipped with mechanical float switches, have an output of 6000 kW each. The biggest danger in this application is the occurrence of hydraulic shock. A good overfill protection system must be able to survive such abrupt pressure surges unscathed. To provide twofold safety, the sensor should be based on a completely different measuring principle. By using two different measuring principles, systemic flaws can be eliminated.

Recommended products

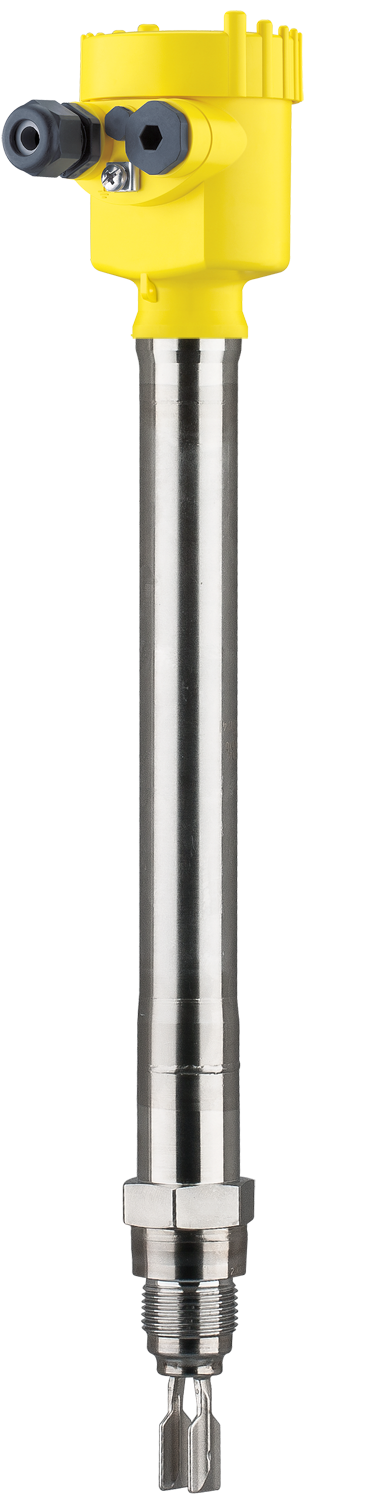

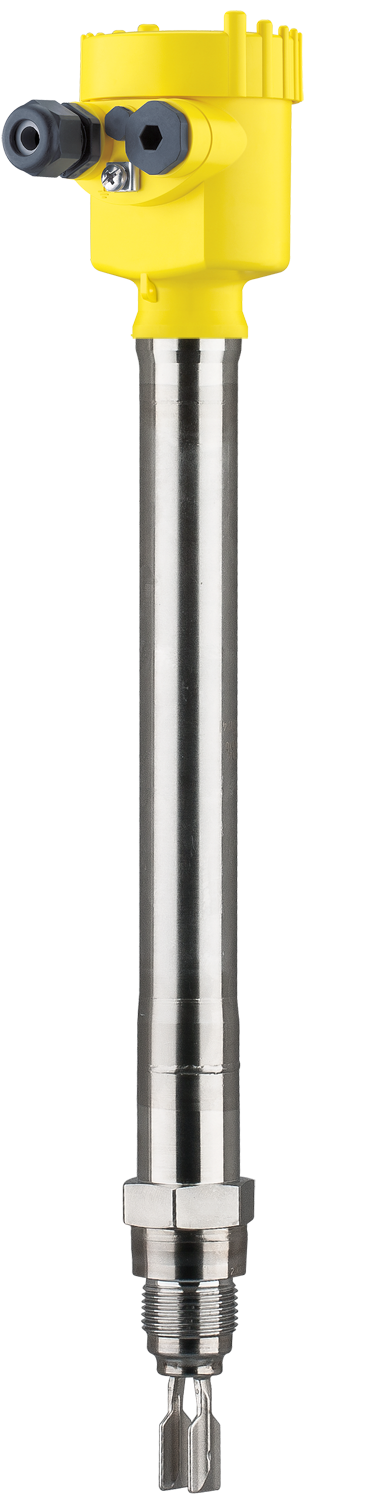

VEGASWING 66

The solution

VEGASWING 66 is the ideal solution for this application.

With a temperature range of -196 ... +450° C and a maximum pressure of 160 bar, it’s just perfect for this demanding measurement task.

From the wide range of options the operator chose a robust aluminium housing and a standard, size G1 threaded fitting. Together with a relay output, the VEGASWING 66 sensor fit like custom made into the existing power plant systems.

This solution increases not only the reliability of the system but also its safety margin. If one of the two overfill protection systems fails, continued, trouble-free operation of the boiler is guaranteed.

User benefits

- Durable and resistant to pressure surges

- Universally applicable - independent of density and dielectric constant of the medium

- Safety ensured through additional, different measuring System

- Accurate, reliable measurement

- Simple adjustment

- Cost savings through greater plant availability

Version

Compact version

with gas-tight leadthrough

with tube extension

Hantar mesej anda ke VG Instruments (SEA) Sdn Bhd