EEPS Cleanroom System Solutions Malaysia

At EEPS Engineering Sdn Bhd, we specialize in delivering high-quality cleanroom systems that ensure contamination control, operational efficiency, and regulatory compliance. Our solutions include Wall & Ceiling Panels, Ceiling Grid Systems, Doors & Windows, and essential cleanroom accessories, all engineered for precision, durability, and ease of installation.

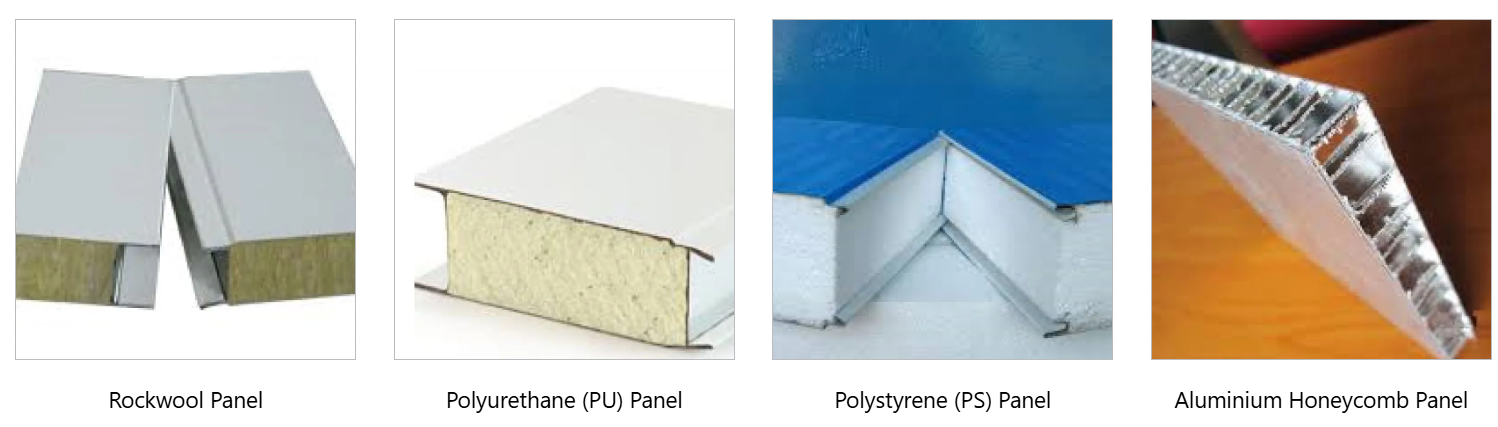

Our panels and systems are designed to resist chemicals, alcohol, scratches, and particle shedding. They include Polystrene (PS), Polyurethane (PU), Aluminium Honeycomb, and Rockwool cores with engineered exterior skins for easy maintenance and long-lasting performance. Installation is quick and precise, with concealed fasteners and no drilling operations required, ensuring fully integrated wall systems compatible with glass windows, doors, and auto-sliding door solutions.

1. Wall & Ceiling Panels

Our wall and ceiling panels are non-outgassing, anti-static, and particle-shedding-free, tested per ASTM E595 standards to minimize contamination. Panels are available in 44mm, 50mm, 75mm thickness, or custom sizes to fit your facility needs.

Product Specifications

| Panel Core | Panel Skin | Applications | Benefits | Technical Data | Variations |

|---|---|---|---|---|---|

| Aluminium Honeycomb | Prepainted Aluminium Sheet | Static Controlled Environments | Easy Cleaning | BS & MS Std | Openings for factory ancillary devices |

| Rockwool | Vinyl Lamination | Anti-Bacteria Grade Skin | No Exposed Fasteners | Natural Anodized / Epoxy Powder Coated Finish | Various core & skin configs |

| Polystyrene (PS) | High Pressure Laminates (HPL) | Controlled Environment | Easy Installation | Standard Sizes: 6mm, 13mm, 55mm | – |

| Polyurethane (PU) | Stainless Steel | Food / Bio Industry | – | Epoxy Adhesive / Colorbond Prepainted Steel | – |

| Prepainted Steel Sheet | Aluminium Honeycomb | – | – | Aluminium Accessories | – |

Panel Types: Rockwool, Polyurethane (PU) Panel , Polystyrene (PS) Panel, Aluminium Honeycomb

2. Ceiling Grid Systems

EEPS provides multiple cleanroom ceiling solutions with extruded aluminium T-grid systems (1”, 2”, 3”) and zinc alloy die-castings for durability and precision.

-

2” T-Grid System: Most cost-efficient, suitable for FSE 100,000 to 10 cleanroom classes or full HEPA coverage applications

-

Enhances structural stability, cleanroom security, and airflow integration

.png)

Grid Models:

-

YECG-1001 – 1” extruded aluminium T-Grid

-

YECG-2002 – 2” cost-effective T-Grid

-

YECG-3003 – 3” heavy-duty T-Grid

.png)

3. Doors & Windows

EEPS cleanroom doors and windows are designed for airtight, contamination-free access and customized layouts.

.png)

Doors:

-

Single Leaf / Double Leaf Doors

-

Core Material: Aluminium Honeycomb / PU / PS / Rockwool

-

Skins: Prepainted Steel / Stainless Steel

-

Hinges: Stainless Steel Standard Type

-

Lockset: Mortise Lever Lock / Cylinder Lock

-

Size: Single Leaf – 900mm(W) x 2100mm(H) x 40mm(T) | Double Leaf – 1800mm(W) x 2100mm(H) x 40mm(T)

Windows:

-

5mm Clear Glass or Acrylic Sheet

-

Customizable: Double glazing, 45° slope, rounded frame

-

Powder-coated aluminium frames for cleanroom wall panel integration

4. Cleanroom Accessories & Equipment

EEPS provides a full range of cleanroom support systems for operational efficiency:

-

Coving & Vinyl Flooring

-

Epoxy Flooring & Raised Floors

-

Clean Booths & Air Showers

-

Fan Filter Units (FFU) & Pass Boxes

.png)

Why Choose EEPS Engineering for Cleanroom Systems in Malaysia?

-

High-Quality Panels & Materials: Non-outgassing, anti-static, and particle-shedding-free

-

Customizable Solutions: Supports all cleanroom classes and configurations

-

Professional Installation: Concealed fasteners, no drilling, and integrated solutions

-

Compliant & Durable: Meets ISO, GMP, and industry cleanroom standards

-

Full Cleanroom Integration: Wall, ceiling, HVAC, filtration, and access systems

-

Local Expertise: Trusted cleanroom contractor in KL, Selangor, and Malaysia

EEPS Engineering delivers reliable, efficient, and cost-effective cleanroom systems that exceed client expectations across industries such as pharmaceuticals, semiconductors, biotechnology, electronics, and food production.