3.2M Grand Format Solvent Injet Printer - Designed for quality at the best price

SWJ-320EA is a revolutionary 3.2 meter wide solvent printer. As the successor of the legendary SWJ-320 S4, its functionality is further expanded with Mimaki Core Technologies such as MAPS4, NRS, and offers an unique ratio of affordable price, highest quality, and reliability.

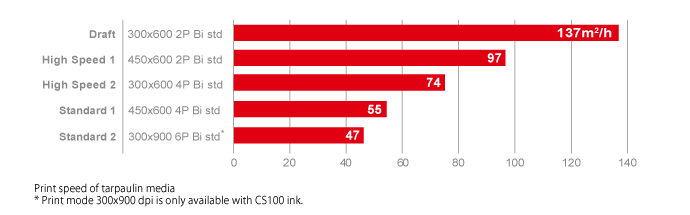

Four advanced printheads with top speeds up to 137sqm/h !

New generation of high-speed print heads arranged in stagger mode with a resolution up to 1200 dpi allows the high speed production at the speed of max. 137sqm/h.

Print speed

Twin-roll printing

Taking advantage of the 3,200 mm printing width, two media rolls can be mounted and can be printed on simultaneously*. This function enables operating different print jobs at once. The user may select the preferable widths separately for each roll within a specified range from 210 to 1,524 mm. Each media width and the distance between the two media rolls are automatically detected.

* The same media type should be used when printing on two media rolls simultaneously.

Proven High Resolution and Print Quality

Mimaki’s world proven technology produces unbeatable high definition and resolution prints. With three different dot sizes (7pl minimum) and a maximum resolution of 900 x 1,200dpi, the SWJ-320EA ensures fantastic print results without that grainy appearance.

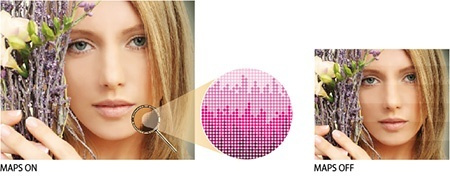

Mimaki Advanced Pass System (MAPS4)

MAPS is designed to prevent banding. With every pass, it uses a unique algorithm that calculates the most effective way of jetting the ink drops to avoid visible banding. This constantly changes depending on ink color, coverage and printing speed.

Nozzle Recovery System (NRS)

Without the nozzle recovery function, when printing and nozzle clogging or failure occurs that could not be resolved by the nozzle cleaning function, printers have to wait stop until the Mimaki service team arrives. When it comes to this function, even if nozzle washing has no effect on a troubled nozzle, the print image quality can be retained immediately without slowing down the print process.

* The recoverability of this function is limited.

| SWJ-320EA | ||

| Head | On-demand piezo head | |

| (4 printheads with 2 staggered configuration) | ||

| Print resolution | 300 / 600 / 900 / 1,200 dpi | |

| Ink | Type/ Color | CS100 solvent ink (C, M, Y, K) |

| CS200 solvent ink (C, M, Y, K) * | ||

| Packaging | 2L bottle / each color | |

| Ink supply system | 3L / each color | |

| Maximum print width | 3,200 mm (126 in) | |

| Maximum media width | 3,250 mm (127.9 in) | |

| (When roll holders are used:1,620mm (63.7 in) × 1) | ||

| (Twin-roll printing with roll holders: 1,524 mm (60 in) × 2) | ||

| Minimum media width | 210 mm (8.2 in) | |

| (Twin-roll printing: 210 mm (8.2 in) × 2) | ||

| Media thickness | 1.0 mm or less | |

| Media Feeding / Take-up device | Equipped | |

| Roll outer diameter | Large drive shaft: Φ250 mm (9.8 in) or less | |

| Roll holder: Φ180mm (7 in) or less | ||

| Roll weight | Large drive shaft: | |

| Feeding: up to 100 kg (220 lb) / Take-up: up to 100 kg (220 lb) | ||

| Roll holder: | ||

| Feeding: up to 25 kg (55 lb) / Take-up: up to 25 kg (55 lb) | ||

| Drying device | 3 Way intelligent heater (Pre/Print/After) | |

| Certifications | VCCI class A, FCC class A, ETL IEC 60950-1 | |

| CE Marking (EMC, Low voltage, Machinery directive, and RoHS), | ||

| CB, REACH, EAC | ||

| Interface | Ethernet 1000BASE-T / USB2.0 | |

| Power specification | AC 200–240V ± 10%��50/60Hz ±1 Hz, 29 A or less | |

| Power consumption | 6.9 kW or less | |

| Operational environment | Temperature: 20–30 °C (68–86 °F) | |

| Humidity: 35–65 %Rh (No condensing) | ||

| Dimensions (W×D×H) | 5,410 mm × 995 mm × 1,440 mm (213 x 39.2 x 56.7 in) | |

| Weight | 850 kg (1873.9 lb) | |

VN 2468

VN 2468  US 1914

US 1914  GB 381

GB 381  CA 312

CA 312  AU 266

AU 266  BR 214

BR 214  CN 146

CN 146  DE 135

DE 135