Cleanroom System Malaysia

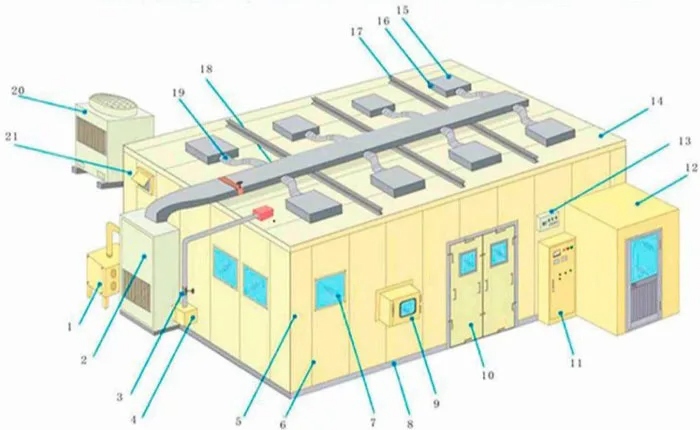

A fully functional Cleanroom System in Malaysia requires more than just clean air—it depends on a complete integration of specialized components that work together to maintain controlled environmental conditions, compliance, and operational efficiency. At EEPS Engineering Sdn Bhd, we design and install advanced cleanroom systems that incorporate critical elements such as Air Showers, Pass Boxes, HEPA filtration, HVAC systems, and precision airflow control. These components ensure effective particle removal, contamination prevention, and stable environmental conditions for high-tech manufacturing and laboratory applications.

Our cleanroom systems are widely used in semiconductor, pharmaceutical, electronics, biotechnology, and healthcare facilities, where strict cleanliness and controlled conditions are essential. By combining robust structural panels, high-quality filtration, and intelligent airflow management, EEPS Engineering delivers reliable, compliant, and high-performance cleanroom environments across KL, Selangor, and Malaysia.

Key Components of Our Cleanroom System

-

Air Shower – Removes contaminants from personnel and materials before entry

-

Pass Box – Safe material transfer without pressure loss

-

Cleanroom Door & Auto Sliding Door – Airtight access control

-

HEPA Filtration System – Ensures high air purity and compliance

-

Fan Filter Unit (FFU) – Maintains uniform airflow distribution

-

Cleanroom HVAC & Air Conditioning System – Temperature and humidity control

-

Air Volume Control Valve & Positive Pressure Exhaust Valve – Balanced airflow

-

Plenum & Main Air Duct System – Efficient air circulation

-

Rockwool & Glass Magnesium Ceiling Panels – Fire-resistant and durable

-

Cleanroom Wall Panels & Observation Windows – Hygienic and scratch-resistant

-

Display Instruments & Distribution Box – System monitoring and control

High-Quality Cleanroom Panel System

EEPS Engineering uses high-quality cleanroom panels with superior surface finishing that is chemical-resistant, alcohol-resistant, and scratch-resistant. Our panels are available in various core materials, including Polystyrene, Polyurethane, Aluminum Honeycomb, and Rockwool, ensuring durability, insulation, and compliance with industry standards.

Our cleanroom panel system features:

-

Quick and easy framing for faster installation

-

Integrated glass windows, doors, and auto sliding doors

-

No drilling required for joints

-

Concealed fasteners for a seamless, hygienic finish

Why Choose Our Cleanroom Solutions in Malaysia?

As an experienced cleanroom contractor in Malaysia, EEPS Engineering specializes in the design, construction, and maintenance of controlled environments that comply with stringent cleanliness and contamination standards. We utilize advanced materials and high-performance cleanroom HVAC systems in Malaysia to meet the specific needs of industries such as pharmaceuticals, electronics, biotechnology, and healthcare.

In Kuala Lumpur (KL), our cleanrooms are built with high-efficiency particulate air (HEPA) filtration, controlled laminar airflow, and durable wall and ceiling systems to create sterile and stable environments. These features help minimize contamination risks during sensitive manufacturing, assembly, and research processes.

We provide end-to-end cleanroom solutions, covering system design, layout planning, HVAC integration, filtration, testing, and certification. With a strong commitment to precision, quality, and compliance, EEPS Engineering delivers cost-effective and reliable cleanroom systems in Malaysia that consistently exceed client expectations.