At Newton Hydraulics Sdn. Bhd., we recently completed a hydraulic press system upgrade for one of our valued customers in Malaysia. The project involved converting a traditional hydraulic system that relied on standard directional and relief valves into a modern proportional control system to achieve smoother operation, higher precision, and improved efficiency.

🔧 Scope of Work:

-

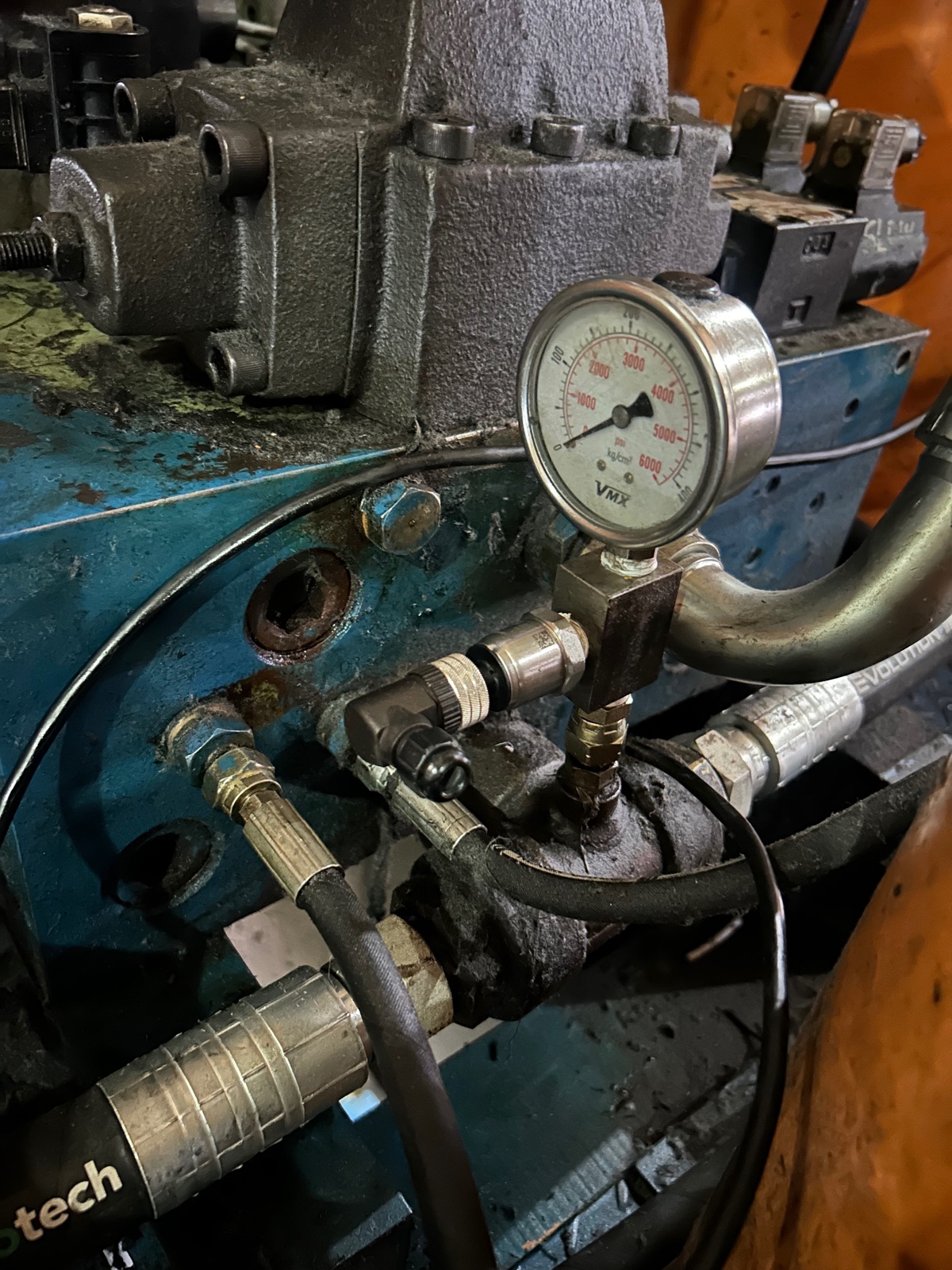

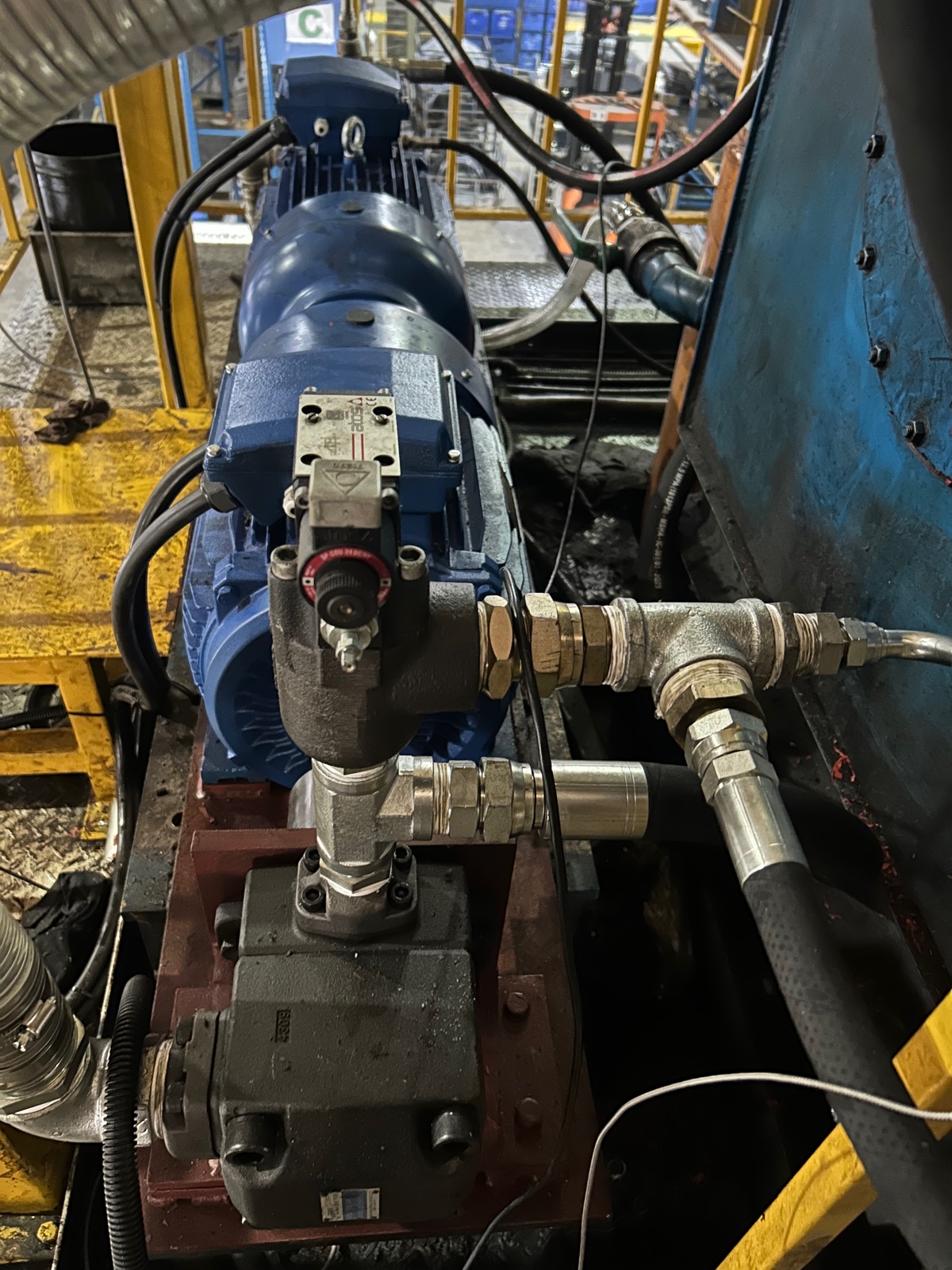

Replaced conventional valves with proportional valves for precise control of pressure and flow

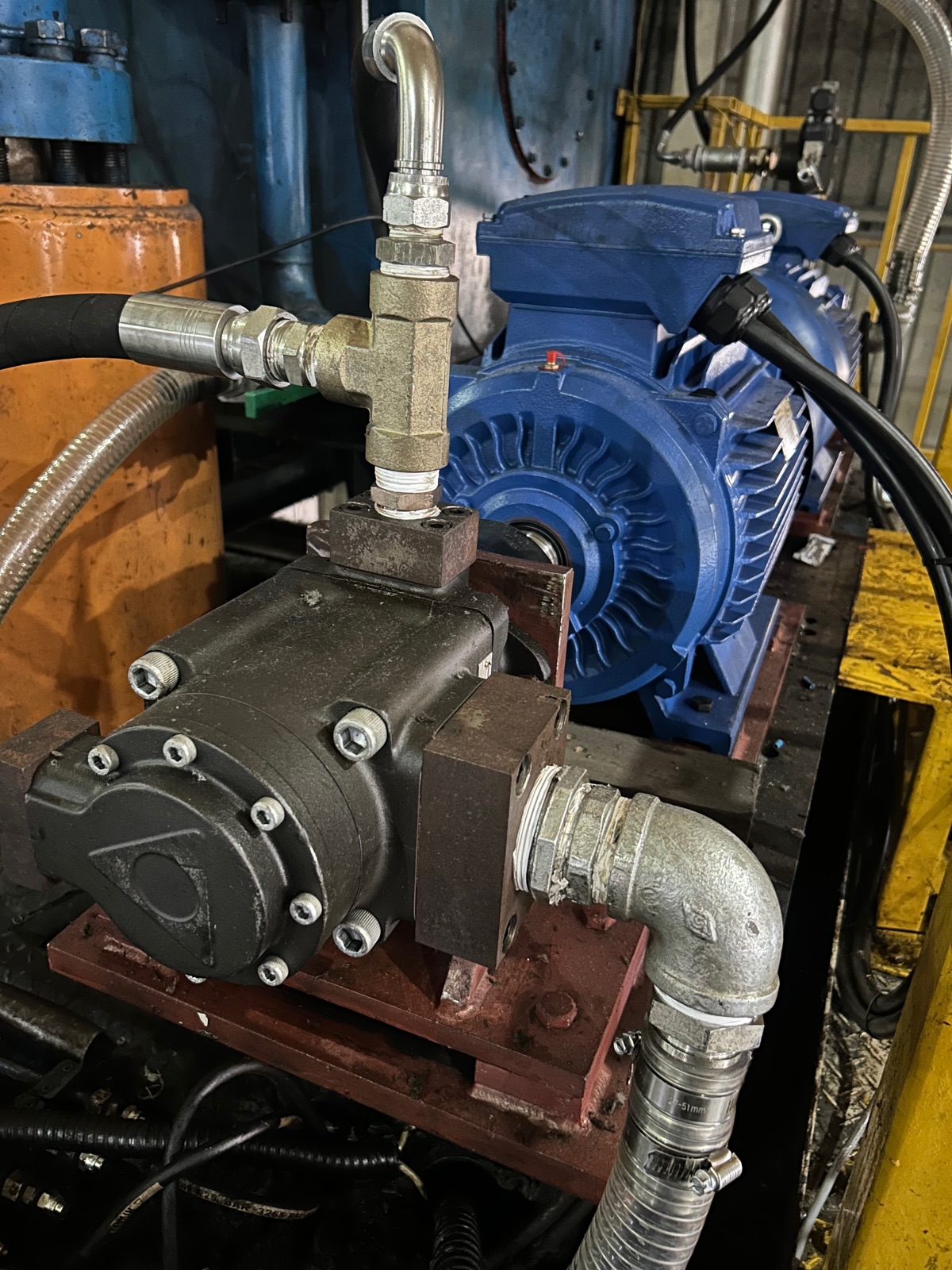

- Replaced old motor and pump with new more efficient motor and pumps.

-

Replaced conventional valves with proportional valves for precise control of pressure and flow

-

Integrated electronic control and feedback system to monitor pressure, temperature, and operation cycles

-

Enhanced press performance by improving response time and repeatability

-

Conducted pressure testing and calibration to ensure stable operation up to 180 bar

-

Installed new hydraulic piping, fittings, and control wiring for optimized performance

⚙️ Key Benefits:

-

Better Press Control: Smooth and accurate pressure regulation

-

Improved Production Efficiency: Faster cycle time and reduced downtime

-

Energy Optimization: Reduced pump load during idle cycles

-

Data Visibility: Display of system readings such as pressure, output quantity, and efficiency

-

Long-Term Reliability: Lower maintenance frequency and improved machine lifespan

🏭 Outcome:

This successful upgrade improved the customer’s press precision, reliability, and productivity, showcasing our expertise in custom hydraulic system upgrades and proportional valve integration.