MCT3000 Series Image Measuring Machine – Precision, Fast, and Multi-Field Applicable

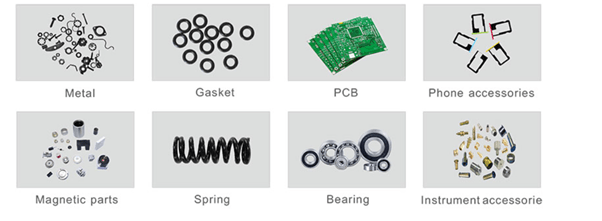

Based on visual measurement principle with precision image analysis algorithms, equipped with double telecentric optical lens with high depth of field, MCT3000 series of Image Measuring Machines achieve fast dimensional measurement by one-key operation. MCT3000 series are suitable for precise dimensional measurement in the fields of machinery, electronics, moulds, injection moulding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical equipment, watches, cutting tools, etc.

Item No.: MCT3300D

Product name: Image Measuring Machine

Image Senor: 5M CMOS

Field of view: W130mm×L230mm & W200mm×L300mm

Depth of Field: 3mm & 30mm

Working Distance: 120mm

Accuracy: ±2μm(Without stitching) & ±5μm(Without stitching)

Resolution: 0.1μm

Loading Capacity: 5kg

Size (LxWxH): 531×503×731mm

Weight: 75kg

Technical Specification

| Model | MCT3300 | MCT3300D | ||

|---|---|---|---|---|

| Image Sensor | 5M CMOS | |||

| Monitor | Built-in | 10.4″ LCD (XGA:1024×768) | ||

| Outside | 24″ LCD (XGA:1920×1080) | |||

| Acceptance Lens | Object Space Telecentric Lens | |||

| Light | Ring | Four-segment illumination (White Light / Green Light) | ||

| Bottom | Telecentric transmission illumination (Green Light) | |||

| Field of View | Large field | 200mm×300mm (4 Angle R50) | 200mm×300mm (4 Angle R50) | |

| High precision | / | 230mm×130mm | ||

| Resolution | 0.1 μm | |||

| Repeatability of Image Meas. |

Large field | Without Stitching*¹ | ±1 μm | ±1 μm |

| With Stitching*² | ±2 μm | ±2 μm | ||

| High precision | Without Stitching*¹ | / | ±0.5 μm | |

| With Stitching*² | / | ±1.5 μm | ||

| Accuracy of Image Meas. |

Large field | Without Stitching*¹ | ±5 μm | ±5 μm |

| With Stitching*² | ±(7+0.02L) μm | ±(7+0.02L) μm | ||

| High precision | Without Stitching*¹ | / | ±2 μm | |

| With Stitching*² | / | ±(4+0.02L) μm | ||

| Height Meas. (Optical probe) (Optional) |

Measuring Range (XY) | 120mm×110mm | ||

| Max Hole-Depth Ratio (h/φ) | 1.5 | |||

| Dia. of Beam | Φ38 μm | |||

| Resolution | 0.25 μm | |||

| Z Non-movement | Range (Z) | ±3.5 mm | ||

| Accuracy | ±2 μm | |||

| Z Movement | Range (Z) | 70 mm | ||

| Accuracy | ±(6+0.01H) μm, H is Z moving height in mm | |||

| Software | VisionX | |||

| XY Object Table | X Travel Range | 210mm (Motorized) | ||

| Y Travel Range | 110mm (Motorized) | |||

| Loading Capacity | 5kg | |||

| Z-Axis Travel Range | 75mm (Motorized) | |||

| Size (L×W×H) | (531×503×731) mm | |||

| Weight | 74kg | 75kg | ||

| Input | AC100~240V/50~60Hz | |||

| Working Environment | Temp.10��~35��, Humidity 30%��80%, Vibration<0.002g, Less than15Hz | |||

Applications

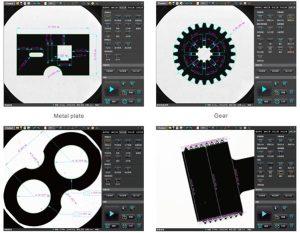

VisionX software provides up to 80 extraction analysis tools, including [Feature Extraction] (such as maximum points, centerlines, arcs, peaks, etc.), [Accessory Tools] (such as any dot & line & circle, fitted straight line, Fit circle, tangent, inscribed circle, etc.), [Smart Labeling], [shape tolerance], and special [Application Tools] (such as pitch distance, pitch angle, slot, thread, round cross, down angle, rounded corners, etc.)

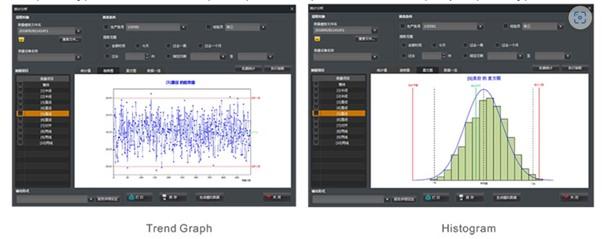

The measurement results and their main statistical values (such as average, σ, 3σ, 6σ, Ca, Cp, Cpk, etc.) will be automatically recorded and archived. Operators can select different filter conditions for history extraction.

Statistics

The trend graph displays the regular trend of the measured values, such as the monotonic and periodic change of the measured values, which can be used for monitoring the abnormality of the production process of producing equipment. Reflecting the status and distribution of fluctuations in product quality, the histogram can intuitively expose information about the quality situation in producing process, which can be used to predict product quality and failure rate.

Through quality diagnosis and analysis with statistical methods, SPC can monitor the product quality and changing trend of the producing process. With SPC we can find the preventive solution in the producing process, so that the subsequent inspection and repair are reduced. Consequently, the producing process control and product quality improvement are achieved.