The Critical Role of CFD in Fan Blade Design and Fluid Mechanics

Introduction

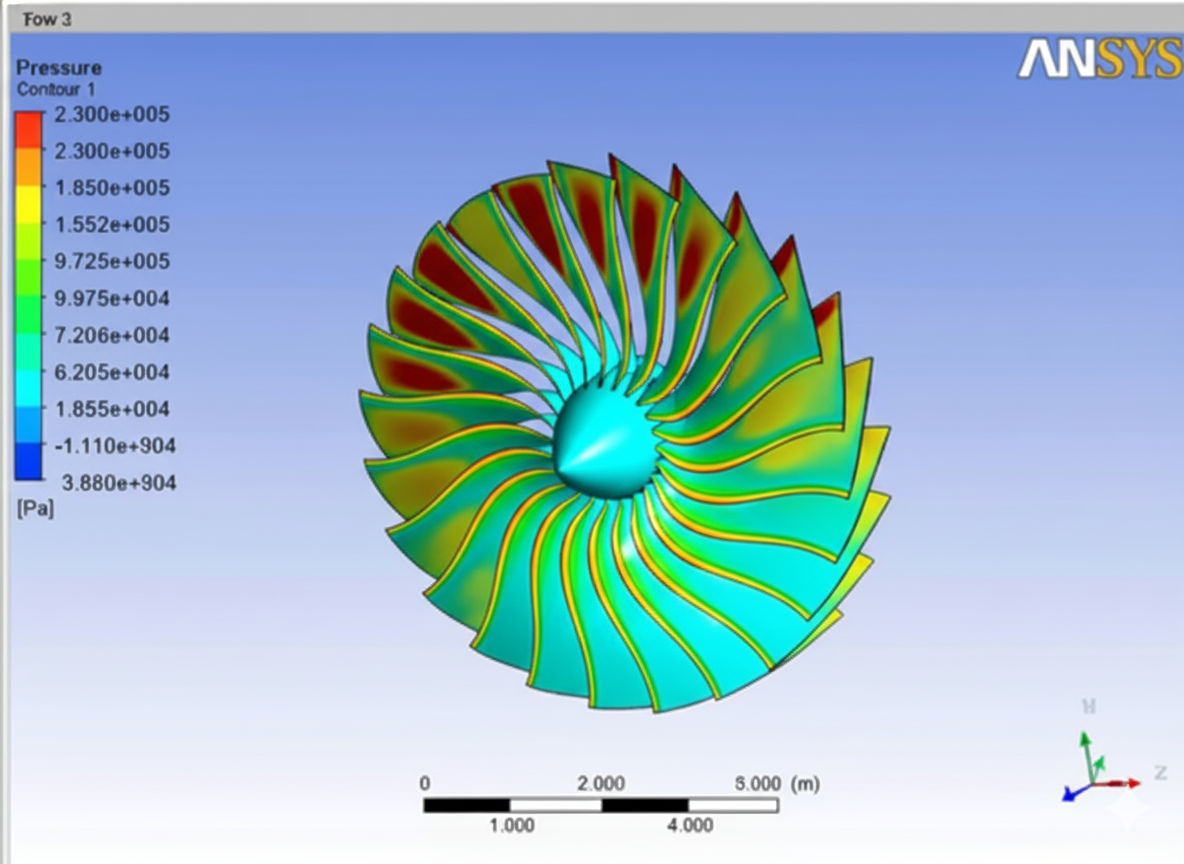

Computational Fluid Dynamics (CFD) has become an indispensable tool in modern engineering, particularly in the design and optimization of fan blades. The performance of a fan—whether in industrial ventilation, HVAC systems, or high-performance turbines—is heavily influenced by aerodynamic efficiency, pressure distribution, and flow behavior. CFD provides engineers with a virtual environment to analyze these parameters with precision, significantly reducing the need for costly physical prototypes.

Understanding Fluid Behavior

Fluid mechanics governs the movement of air or gas around fan blades. Accurate prediction of flow patterns, turbulence, boundary layers, and wake formation is critical for optimal design. CFD allows engineers to model complex fluid behavior under various operating conditions. This includes laminar and turbulent flow, compressible and incompressible regimes, and multi-phase interactions when necessary. Traditional analytical methods or empirical testing cannot capture these complexities with the same level of detail.

Design Optimization

Fan blade design requires balancing efficiency, noise reduction, and structural integrity. CFD enables parametric studies where multiple blade geometries, angles, and curvatures can be tested virtually. By analyzing velocity fields, pressure distributions, and vortex formation, designers can identify designs that maximize airflow and minimize energy losses. CFD also helps predict performance under off-design conditions, which is essential for real-world applications where fans rarely operate at nominal conditions.

Reducing Physical Testing Costs

Traditionally, fan blade design relied heavily on experimental testing, such as wind tunnels and full-scale prototypes. These methods are expensive and time-consuming. CFD reduces dependency on physical testing by allowing engineers to iterate quickly in a virtual environment. Virtual prototypes can reveal potential issues, such as flow separation, cavitation, or noise hotspots, before any physical manufacturing occurs.

Enhancing Safety and Reliability

In high-speed fans and turbines, improper blade design can lead to vibrations, fatigue, or catastrophic failure. CFD allows for the simulation of structural-fluid interactions, enabling engineers to identify stress concentrations and resonance points. This ensures safer, more reliable fan operation while extending the lifespan of the components.

Integration with Modern Engineering Tools

CFD integrates seamlessly with CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) software. This integration streamlines the design process, allowing iterative improvements without leaving the digital environment. Optimization algorithms, such as adjoint methods, can automatically modify blade geometry based on CFD results to achieve the best possible performance.

Conclusion

CFD has revolutionized fan blade design by providing a detailed understanding of fluid behavior, enabling efficient design optimization, reducing costs, and enhancing reliability. For engineers in fluid mechanics, CFD is not just a tool—it is an essential part of the design and validation process, ensuring that fans meet performance, efficiency, and safety requirements in real-world applications.

VN 19704

VN 19704  BR 8893

BR 8893  AR 7665

AR 7665  US 6313

US 6313  EC 2911

EC 2911  CN 2410

CN 2410  MX 2207

MX 2207  CO 1927

CO 1927