Barcode Weighing and Printing System – Smart Solution for Food Factory Management

In modern food manufacturing, precise weight management, quality control, and traceability are critical. Sin Huat Hin Machinery (M) Sdn Bhd offers a Barcode Weighing and Printing System, integrating high-precision weighing, barcode scanning, and printing to provide automated, digital, and intelligent production management for food factories.

This system improves production efficiency, reduces human errors, and ensures that each batch of food products has accurate weight, specification, production date, and batch information, ensuring food safety and regulatory compliance.

System Overview

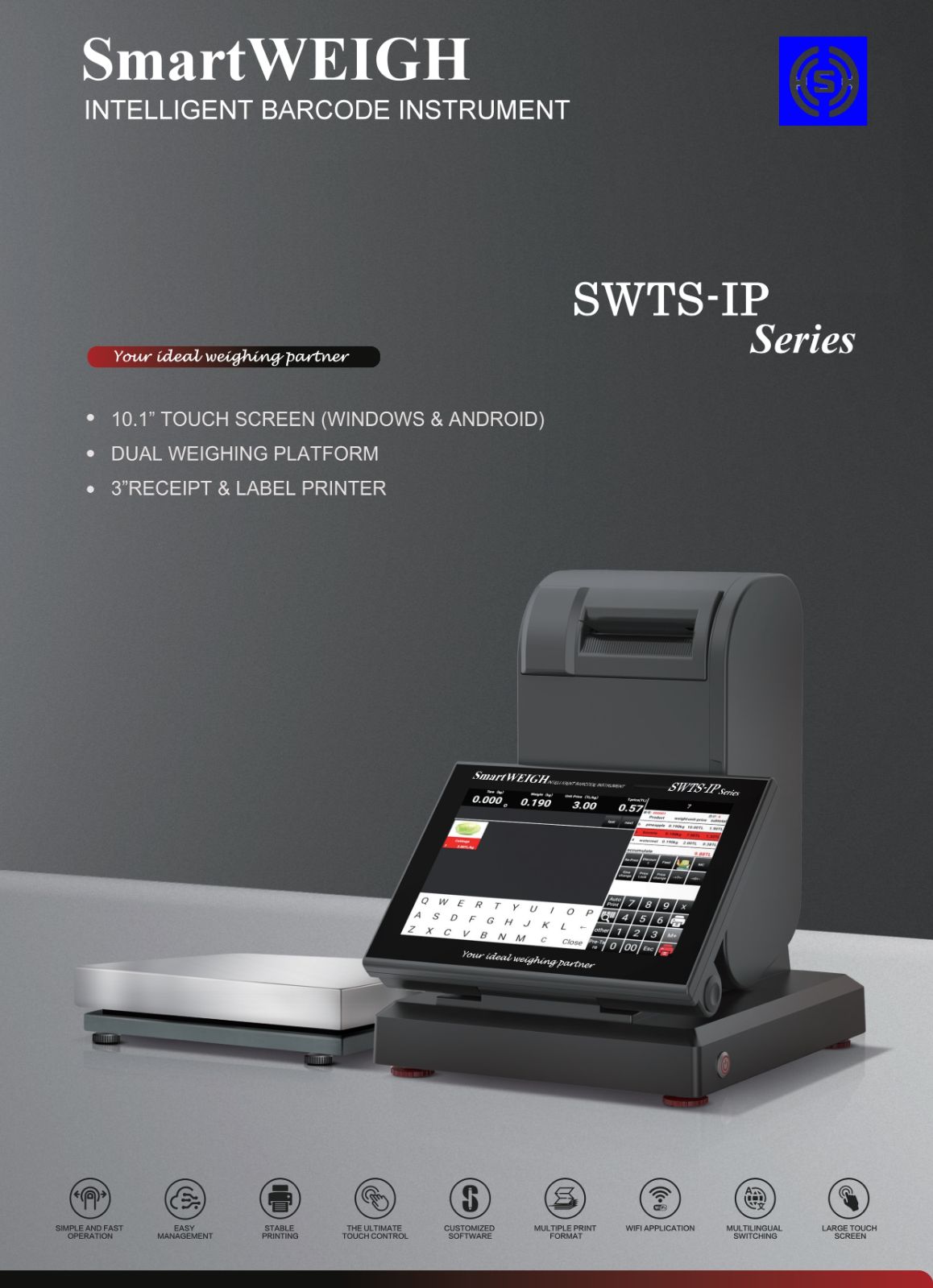

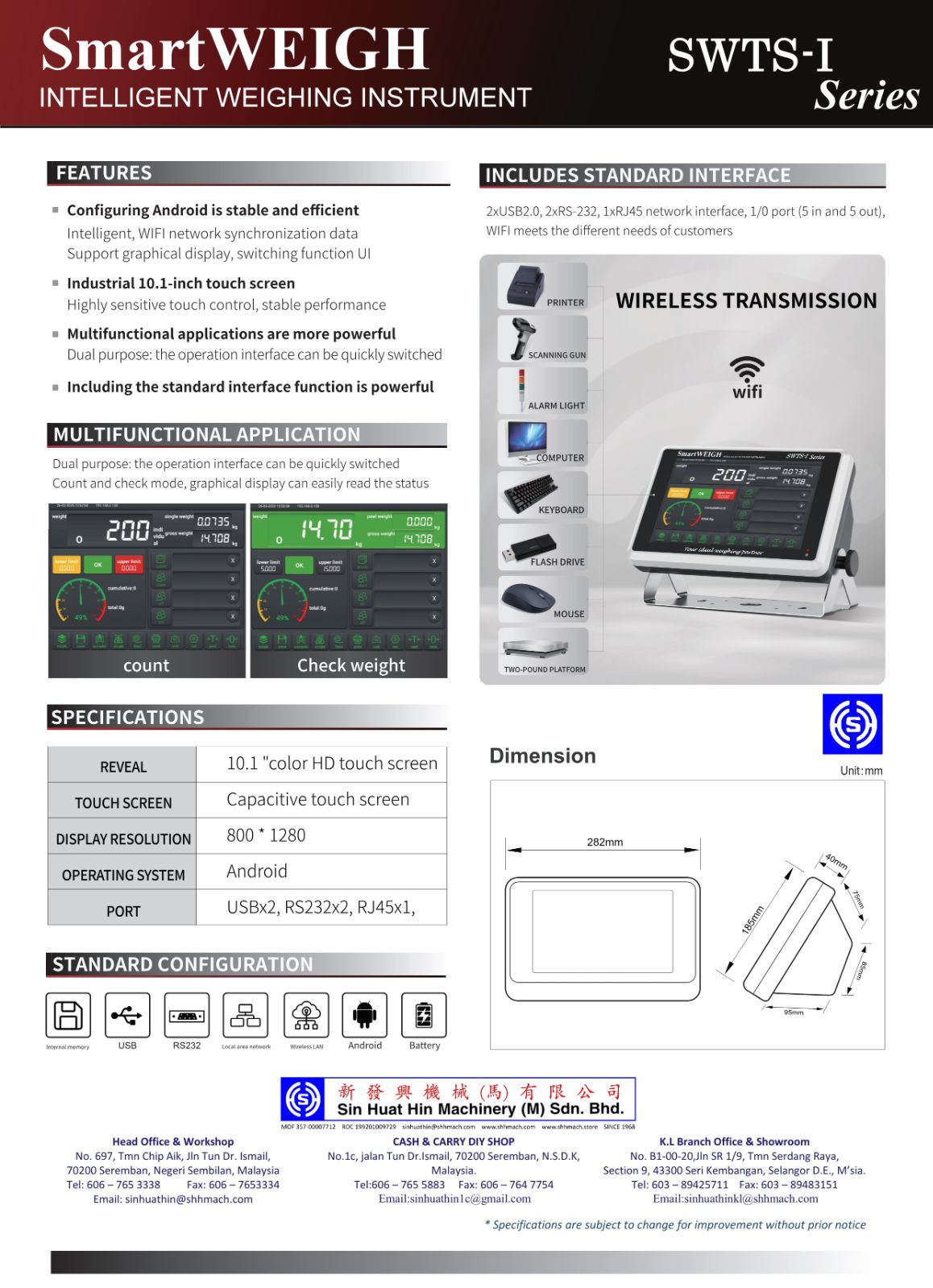

The Barcode Weighing and Printing System combines weighing, barcode scanning, printing, and data recording. Core functions include:

-

Automatic product identification via barcode or QR code

-

High-precision weighing to prevent underweight or overweight products

-

Label or production record printing for traceability

-

Data storage and management for complete production tracking

Applicable in raw material intake, food processing, semi-finished product handling, final packaging, and logistics.

Challenges in Food Factories

Food factories often face:

-

Inconsistent product weights affecting quality and customer satisfaction

-

Low production efficiency due to manual weighing and record-keeping

-

Difficulty in data traceability

-

Strict food safety regulations like ISO22000 and HACCP

The system addresses these challenges effectively.

Applications in Food Factories

1. Raw Material Management

-

Accurate weighing of raw materials to ensure recipe consistency

-

Automatic recording of batch, supplier, and weight information

-

Label printing for raw material identification

2. Food Processing

-

Automatic weighing of semi-finished products such as dough, sauces, or liquids

-

Recording production data for quality management and traceability

-

Integration with production lines for automation

3. Final Product Packaging

-

Accurate weighing of each product and classification by weight

-

Label printing with weight, production date, batch number, and barcode

-

Data recording for full traceability of each product

4. Data Tracking & Quality Control

-

Analyze production efficiency

-

Monitor packaging accuracy

-

Track raw material usage and waste

-

Trace quality issues to specific batches

Technical Features

-

High-precision sensors (±0.1% accuracy)

-

Supports multiple barcode and QR code formats

-

Automatic label and record printing

-

Data export to Excel, ERP, or cloud systems

-

Industrial design for dust, moisture, and low-temperature environments

-

Multi-language interface, customizable for factory needs

Benefits for Food Factories

-

Increase production efficiency through automation

-

Reduce human errors with automatic data recording

-

Ensure food safety and product consistency

-

Optimize raw material usage and reduce waste

-

Support regulatory compliance with ISO22000, HACCP

Case Study

A dairy factory using the system achieved:

-

Raw material weighing accuracy improved to ±0.05%

-

Semi-finished and final packaging efficiency increased by 35%

-

Data traceability improved from 65% to 100%

-

Full ERP integration enabling end-to-end digital management

Conclusion

Sin Huat Hin Machinery (M) Sdn Bhd’s Barcode Weighing and Printing System enhances production efficiency, ensures product quality, and provides complete traceability, meeting stringent food safety regulations. It is the ideal solution for digital transformation in modern food factories.