Trusted & Certified Weighing Scale Calibration Services for All Brands in Malaysia

Precision, Compliance, and Reliability — Delivered by Sin Huat Hin Machinery (M) Sdn Bhd

Accuracy is the foundation of every successful weighing operation. In industries where measurement determines cost, quality, and safety, even a minor deviation in weight can lead to losses, disputes, or operational inefficiencies. For more than five decades, Sin Huat Hin Machinery (M) Sdn Bhd has been Malaysia’s trusted authority in professional weighing scale calibration services, offering certified, traceable, and industry-compliant calibration solutions for businesses nationwide.

As a leader in the weighing industry, we ensure your weighing equipment performs with consistency and integrity—whether it is a compact retail scale, a laboratory analytical balance, a platform scale, or an industrial weighbridge capable of handling trucks over 100 tons. Our services are engineered to support industries that cannot afford inaccuracies.

We Calibrate All Weighing Scale Brands in Malaysia — Without Exception

Our calibration specialists are trained and equipped to service every major global weighing brand, including but not limited to:

ARROW, A&D Weighing, Avery Weigh-Tronix, Precia Molen, TANAKA, KUBOTA, Mettler Toledo, SEWHA, HOLBRIGHT, PT200M, Rinstrum, DIGI, Rice Lake Weighing Systems, EXCELL, ADAM, FINE, Yamato, Curiotec, Jadever, Cardinal, CAS, RONGTA, DINI ARGEO, TSCALE, SmartWEIGH, DICKSON, LAUMAS, Vishay, Sartorius, Ishida, Bizerba, Fairbanks, Salter, Minebea Intec, OHAUS, Detecto, Brecknell, RADWAG, KERN, Dibal, Marel, SENSOCAR — and many more.

From entry-level devices to high-precision engineering-grade instruments, our team is capable of performing all necessary calibration, adjustments, verification tests, and fine-tuning to restore optimal performance.

Why Calibration Is Critical in Modern Industry

Weight measurement is integral to countless industries in Malaysia, including:

-

Manufacturing and industrial production

-

Cold chain logistics and warehousing

-

Food and beverage processing

-

Chemical and pharmaceutical industries

-

Palm oil mills and agricultural operations

-

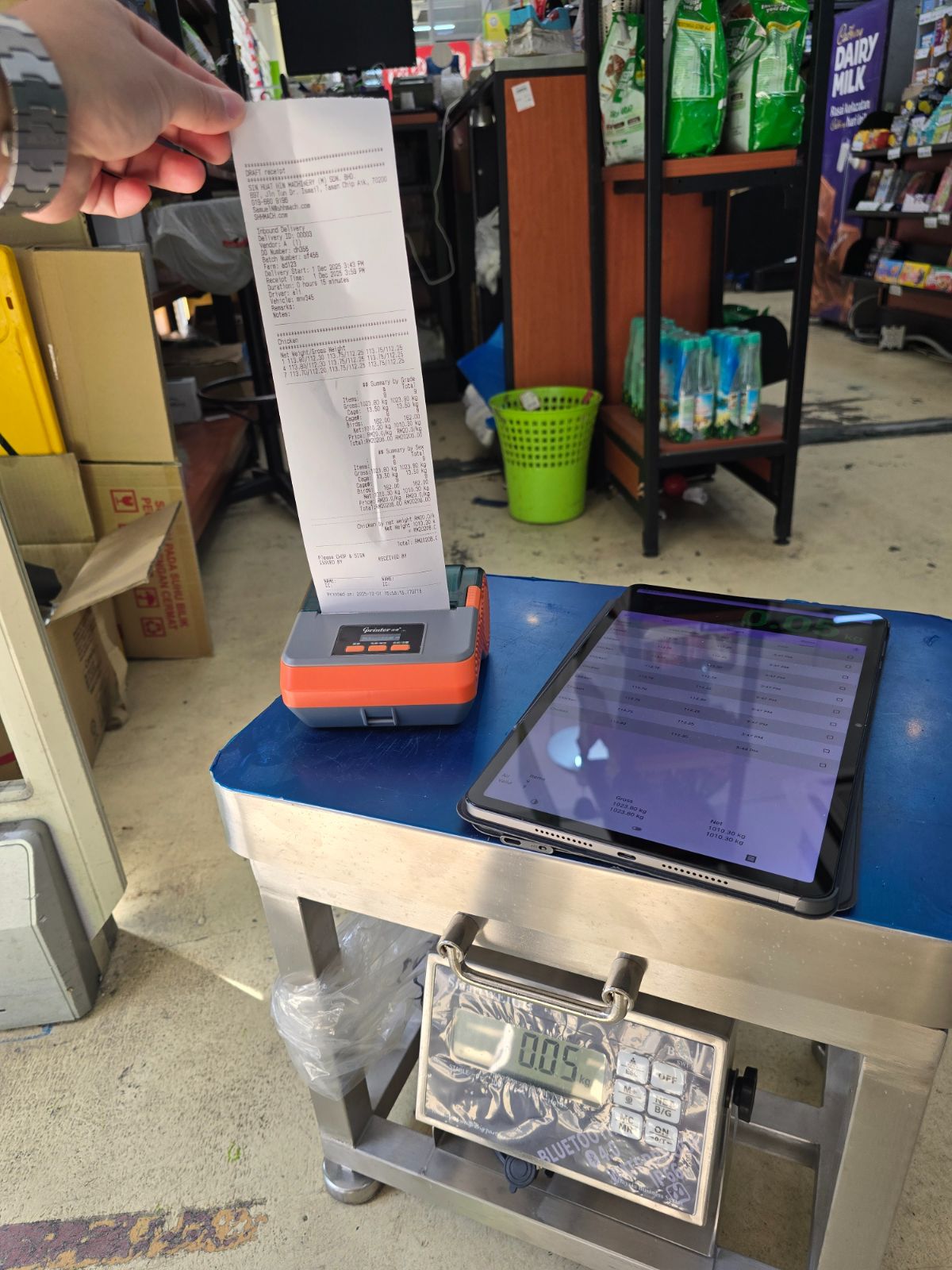

Retail and commercial outlets

-

Electronics and semiconductor production

-

Construction, recycling, and mining

-

Scientific laboratories and R&D institutions

Across all these sectors, weight accuracy is linked to:

Financial accuracy & transaction fairness

Billing and trade transactions depend on trustworthy weight readings.

Quality assurance & traceability

Incorrect measurements lead to inconsistent products and rejected batches.

Safety and compliance

Improper calibration can result in hazardous outcomes, especially in chemical or industrial settings.

Improved efficiency and reduced downtime

Accurate scales ensure smooth workflow, optimized processes, and fewer disruptions.

Extended lifespan of weighing equipment

Calibration identifies potential issues early, reducing repair costs and preventing equipment failure.

Weight deviation, if left unchecked, can cause cumulative losses and long-term operational damage. This is why periodic calibration is essential—and why your business deserves professionals who understand the science behind accuracy.

Types of Weighing Equipment We Calibrate

Sin Huat Hin offers comprehensive calibration services covering the full spectrum of weighing technologies:

1. Bench Scales & Tabletop Scales

Used in F&B, manufacturing, packaging, retail, and many commercial environments, these scales require frequent verification due to daily wear and temperature or humidity influence.

2. Industrial Floor & Platform Scales

Designed for heavier loads in warehouses and factories, these scales must be calibrated under realistic operating loads to maintain reliability.

3. Weighbridges & Truck Scales

One of our strongest specializations.

We perform on-site weighbridge calibration using certified test weights and concrete/steel block loads for capacities ranging from:

-

20 tons

-

40 tons

-

60 tons

-

80 tons

-

100 tons and above

We also handle pit and pit-less models, analog and digital load-cell systems, steel deck and concrete deck platforms, and multi-section weighbridges.

4. Belt Weighers & Conveyor Weighing Systems

Dynamic weighing requires special calibration procedures.

We calibrate:

-

Belt scales

-

Conveyor weighers

-

In-motion scales

-

Checkweighers

-

Hopper and batching scales

Our methods include static calibration, dynamic calibration, test weights, chain calibration, and parameter optimization.

5. Precision & Analytical Laboratory Balances

Laboratory instruments demand micro-accuracy.

We provide:

-

Microbalance calibration

-

Analytical balance calibration

-

High-resolution laboratory scale calibration

-

Environmental error analysis

-

Sensitivity and linearity checks

We ensure measurement integrity for industries with zero tolerance for errors.

6. Load Cell Modules, Indicators & OEM Weighing Systems

Advanced weighing applications require deep technical knowledge.

We provide calibration and diagnostic analysis for:

-

Single-point load cells

-

Compression load cells

-

Shear beam load cells

-

S-type and tension load cells

-

Digital weigh indicators

-

Programmable controllers

-

PLC-integrated weighing modules

Our technicians analyze signal drift, hysteresis, non-linearity, noise interference, and parameter deviation.

Our Calibration Process — Trusted, Certified & Traceable

Every calibration service is conducted according to international and industry-recognized standards, including OIML, ISO, ASTM, and other metrology guidelines.

Our process includes:

1. Pre-Calibration Evaluation

We analyze the equipment’s condition, environment, temperature, humidity, and installation.

2. Test Weight Comparison

Using certified weights traceable to national and international standards, we perform step tests, span tests, linearity tests, repeatability tests, and corner load tests.

3. Fine Adjustment & Optimization

If deviations are identified, we adjust internal parameters to restore ideal performance.

4. Diagnostic Checks

We inspect electronics, load cells, cables, junction boxes, and environmental influence.

5. Performance Verification

After adjustments, tests are repeated to ensure stability and compliance.

6. Calibration Certificate Issuance

You receive a full calibration report for:

-

auditing

-

quality assurance

-

regulatory compliance

-

customer records

Certificates include traceability data, measurement uncertainties, and detailed test results.

On-Site and In-House Calibration Available

We offer two calibration service modes depending on your business needs:

On-Site Calibration

Suitable for:

-

weighbridges

-

industrial scales

-

floor scales

-

platform scales

-

conveyor weighing systems

Our team arrives equipped with weights, tools, and diagnostic instruments to perform calibration directly at your facility.

In-House Calibration

Ideal for:

-

compact scales

-

precision balances

-

analytical laboratory equipment

-

small retail and commercial scales

In-house calibration ensures controlled temperature, humidity, and environment for high-accuracy instruments.

Industries We Support

Our services cover nearly every Malaysian industry, including:

-

Manufacturing

-

Palm oil milling operations

-

Chemical and pharmaceutical factories

-

Food & beverage production

-

Agriculture and plantation businesses

-

Logistics, warehousing, and transportation

-

Retail and commercial trading

-

Laboratories and research centers

-

Metal, recycling, and construction industries

With 50+ years of hands-on experience, we understand the challenges each industry faces—and we know how to solve them effectively.

Common Calibration Issues We Can Fix

Our experts diagnose and resolve problems such as:

-

drifting readings

-

unstable or fluctuating values

-

slow response

-

non-linearity

-

incorrect zero-point

-

load cell malfunction

-

indicator communication issues

-

environmental vibration interference

-

electronic circuit inconsistency

-

cable fault or junction box errors

No matter the issue, we deliver fast, practical, and accurate solutions.

Why Businesses Choose Sin Huat Hin Machinery

Over 50 years of technical expertise

Established since 1968.

Calibration for ALL scale brands

No limitation—local, imported, discontinued, or OEM.

Certified, traceable calibration

Audit-ready documentation.

Fast response & nationwide coverage

Available anywhere in Malaysia.

Reliable results & long-term accuracy

Our services extend the lifespan of your weighing systems.

Preventive maintenance programs

Reduce downtime and prevent costly breakdowns.

When Should You Calibrate Your Weighing Equipment?

You should schedule calibration if:

-

Your scale displays inconsistent or unstable readings

-

It has been more than 6–12 months since the last calibration

-

You are preparing for a customer audit or certification

-

You have replaced load cells or indicators

-

The scale has been relocated

-

Quality control reported deviations

-

Your weighbridge is used for legal trade

-

You suspect measurement errors

Proactive calibration protects your business from loss, disputes, and operational disruption.

Accuracy Matters. Reliability Matters. Your Business Matters.

Let our calibration experts ensure your weighing systems perform at the highest level of accuracy and compliance.

Contact Sin Huat Hin Machinery today to arrange your calibration service.