Furthermore, it has multiple motor protection functions, fundamentally solving many drawbacks of traditional reduced-voltage starting devices.

Thyristor Soft Starter Principle

The thyristor soft starter uses a PWM wave emitted by the control unit to control the thyristor trigger pulse, thereby controlling the thyristor's conduction and thus controlling the motor start. Before analyzing the soft starter principle, the following terms should be emphasized:

(1) Trigger angle α: The electrical angle corresponding to the period from the positive voltage of the thyristor to the application of the trigger pulse.

(2) Conduction angle θ: The angle corresponding to the conduction time of the thyristor within one cycle.

(3) Freewheeling angle φ: The phase angle at which the inductive load current lags behind its corresponding phase voltage.

(4) Turn-off angle δ: The angle from the moment the current reaches zero until the thyristor of that phase turns on again. The working principle of thyristor soft starting is to control the conduction angle of the three anti-parallel thyristors connected in series between the power supply and the controlled motor, thereby raising the motor terminal voltage from a preset value to the rated voltage. The starting torque of a three-phase AC asynchronous motor is directly related to the square of the applied voltage; that is, reducing the voltage at the motor terminals will affect these values.

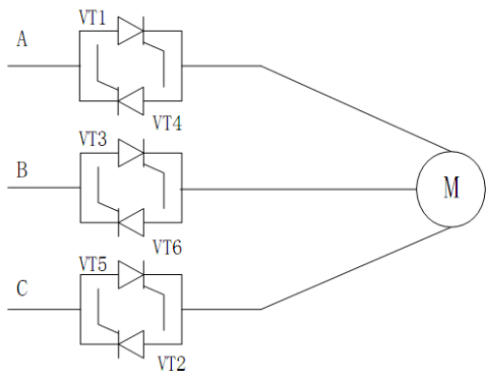

Figure 1 shows the main circuit diagram of thyristor voltage regulation soft starting. The voltage regulation circuit consists of six thyristors connected in anti-parallel pairs, connected in series in the three-phase power supply line of the motor. During startup, the thyristor firing angle is controlled by software. When the starter's microcomputer control system receives the startup command, it performs relevant calculations and outputs a signal to trigger the thyristors. By controlling the thyristor conduction angle θ, the starter adjusts the output voltage according to the designed mode, causing the voltage applied to the three-phase stator windings of the AC motor to gradually and smoothly rise from zero to full voltage. Simultaneously, the current detection device detects the three-phase stator current and sends it to the microprocessor for calculation and judgment. When the starting current exceeds the set value, the software controls the voltage increase to stop until the starting current drops below the set value, after which the motor continues to increase voltage and start. If the three-phase starting current is unbalanced and exceeds the specified range, starting is stopped. After the startup process is complete, the soft starter engages the bypass contactor, short-circuiting all thyristors, allowing the motor to directly connect to the power grid to avoid unnecessary energy loss. Furthermore, according to the principles of motor theory, when the input power frequency of the motor remains constant, the output torque of the motor is proportional to the square of the input voltage. Therefore, soft starting not only achieves boost current-limiting starting by allowing the stator voltage to increase continuously and smoothly, but also reduces the impact of the motor's starting torque.

Advantages of Thyristor High-Voltage Soft Starters:

1. Wide applicable voltage and power range, compatible with motors from 6kV to 10kV/600kW to 22MW;

2. Soft start and soft stop functions, comprehensively ensuring safe start and stop of the system;

3. Smooth current rise from zero to the set value during motor start-up, ensuring stable starting;

4. Mechanical benefits: Reduces mechanical shock, prevents overvoltage and water hammer effects, and extends the service life of the transmission mechanism;

5. Electrical benefits: Reduces starting inrush current by 50%, extends motor life, and reduces grid voltage fluctuations and their impact on other power users;

6. Enables soft stop, eliminating the impact and damage to certain equipment caused by sudden shutdown;

7. Comprehensive protection functions, preventing personal injury accidents;

8. High degree of intelligence, simple setup and operation;

9. Small size, saving on infrastructure investment;

10. Reduces the capacity of power supply equipment, saving project investment costs.

Technical Features

1. Utilizes a thyristor valve as the main circuit component, featuring advanced technology, reliable operation, modular structure, and easy maintenance;

2. Employs fiber optic transmission technology to isolate high and low voltage components;

3. Employs modern advanced digital signal processing and system integration technology, resulting in superior performance, high reliability, and stability;

4. Employs a series of anti-interference measures, providing strong electromagnetic compatibility;

5. Uses a large-screen LCD display and membrane switch-based controller, offering simple operation and a user-friendly human-machine interface.

BR 19939

BR 19939  VN 13709

VN 13709  US 5813

US 5813  AR 3345

AR 3345  MY 2757

MY 2757  IQ 2425

IQ 2425  MX 2278

MX 2278  ID 1905

ID 1905