Features :

- Patented Design

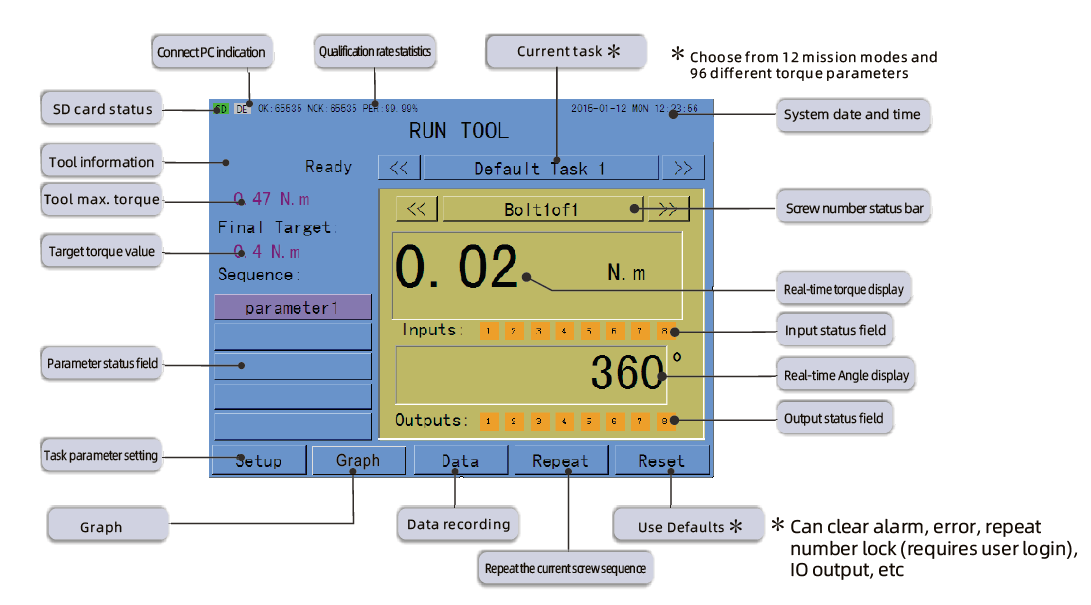

- TFT-LCD monitor able to display the setting, programming and status of the machine

- Lots of task modes that can be used for multiple assembly requirements

- Up to 8 different torque parameter settings per task

- Built-in servo driver can provide precise control of torque, corner monitoring and deceleration tightening

- Provides graphical tools for process optimization and diagnostics

- Programmable IO and system extension components for process control

- Communication interface for advanced data storage and factory control interactions

- Dual operation and monitoring functions, such as physical button and LED indicator light, to further improve the reliability of the controller

Interface :

Advantages :

- Wide Torque Range Coverage:

- Supports a wide torque range, meeting the tightening requirements of various applications. (From securing small screws in 3C industries like mobile phones to meeting high torque demands in heavy industries like automotive manufacturing) Custom screw driver bits can be made according to customer needs.

- Supports a wide torque range, meeting the tightening requirements of various applications. (From securing small screws in 3C industries like mobile phones to meeting high torque demands in heavy industries like automotive manufacturing) Custom screw driver bits can be made according to customer needs.

- One-stop service

- Comprehensive package available: includes intelligent screw machine, controller, software, screws, air blowers, screw feeders, balancing arms, and screwdriver bits.

- Digital control (torque, speed, Angle)

- With unique control technology, torque values during the Tightening process can be set and managed, enabling complete digital control of torque, speed, and angle.

- With unique control technology, torque values during the Tightening process can be set and managed, enabling complete digital control of torque, speed, and angle.

- High precision

- The torque precision can reach ±5%, fulfilling product quality control requirements.

- The torque precision can reach ±5%, fulfilling product quality control requirements.

- Superior Performance

- Advanced Japanese motor technology, offering higher dynamic response and more stable torque output, meeting the needs of various extreme tightening processes.

- Advanced Japanese motor technology, offering higher dynamic response and more stable torque output, meeting the needs of various extreme tightening processes.

- Long Lifespan

- Features permanent magnet synchronous servo motors, ensuring a longer product lifespan.

- Features permanent magnet synchronous servo motors, ensuring a longer product lifespan.

- Data Monitoring and Traceability

- Collects data and handles anomalies, displaying real-time tightening data including torque, angle, and time, and reducing rework costs due to issues like floating or stripped screws.

- Collects data and handles anomalies, displaying real-time tightening data including torque, angle, and time, and reducing rework costs due to issues like floating or stripped screws.

- Storage Data

- Local storage capacity for 600 days of tightening records, with support for data upload.

- Local storage capacity for 600 days of tightening records, with support for data upload.

- Multiple Tightening Strategies

- Capable of implementing various strategies like single-step, two-step, self-tapping, and mating surface, customizable for various applications.

- Capable of implementing various strategies like single-step, two-step, self-tapping, and mating surface, customizable for various applications.

- Industrial Design

- Egonomically designed to increase comfort.

- Egonomically designed to increase comfort.

- Visual Display

- Equipped with a screen and LED lights for better visibility and faster problem identification, improving problem-solving efficiency.

- Equipped with a screen and LED lights for better visibility and faster problem identification, improving problem-solving efficiency.

- Multiple Communication Methods

- Supports RS232, RS485, Ethernet, and other communication protocols, enabling high-speed Ethernet access and strong expandability

Applications :

.png)

Dimension :

.png)

Specifcations :

| Parameter | Description |

| Input voltage | AC 85~264V, 47~63HZ |

| No-load consumption [1] | < 20 W |

| Output power [2] | 40 W |

| Display (Operation interface) | �� TFT-LCD, Touch Screen support �� 3 function buttons + 3 LEDindicators |

| Torque accuracy | (30%~80%) Within the maximum outputtorque range ≤ 3 �� ± 5%, else ≤ 3 �� ± 8% |

| The smallest unit of twist angle display | 1 degree (1°) |

| Tightening method | �� Torque as priority (angle simultaneous monitoring secondly) �� Angle as priority torque simultaneous monitoring secondly) |

| IO channel | 8 CHOptocouplerisolated input (20mA/CH, Max, 8 CH relay contact output (3A/CH, Max |

| Communication interface [3] | �� RS232 �� RS485 �� Ethernet �� RS232+Ethernet |

| Recommended use environment | Temperature-10C~ + 60C, humidity <90% RH (no condensation) |

| Storage environment | Temperature-20C~ + 85-C, humidity<90% RH (no condensation) |

| Weight | About 3.5kg |

| Dimensions | Please refer to "Size drawing" |

BR 5977

BR 5977  US 4707

US 4707  CN 2469

CN 2469  IN 2236

IN 2236  AR 1213

AR 1213  GB 974

GB 974  VN 965

VN 965  MX 896

MX 896