Scantech’s TrackScan Series offers an impressive tracking range, allowing for scans of large components with a tracking distance of up to 8.5 meters and a measurement volume reaching 135 m³. This extensive range allows you to scan large parts without repositioning the object, reducing time and enhancing workflow efficiency, especially for large-scale assemblies and components.

Designed with flexibility in mind, the TrackScan 3D scanners feature wireless functionality, eliminating the need for cumbersome cables. With a built-in processor and wireless communication, these scanners offer smooth, fast, and flexible scanning. The lightweight and portable design enable quick adaptation to a variety of scanning environments, even in hard-to-reach or confined spaces, making them ideal for mobile scanning tasks.

3. Speed and Precision

With a scanning rate of up to 4.86 million measurements per second and 99 laser lines, the TrackScan Series is engineered for high-speed, high-accuracy scanning. The volumetric accuracy of up to 0.048 mm ensures that every measurement is precise, making the system perfect for detailed inspections, reverse engineering, and dimensional analysis.

4. Fine Detail Scanning Mode

For intricate and complex components, the TrackScan Series includes a fine scanning mode equipped with 17 parallel laser lines. This mode captures even the smallest features with exceptional accuracy, making it ideal for applications that require detailed geometric analysis, such as mold inspections, part design verification, and reverse engineering.

5. Seamless Software Integration

In the automotive industry, precision is critical. Scantech’s TrackScan is used for measuring and inspecting vehicle parts, from chassis to exhaust systems. It helps in reverse engineering, ensuring parts fit correctly and are free from defects. Moreover, it streamlines the production process by improving the design and assembly phases, reducing errors, and minimizing rework.

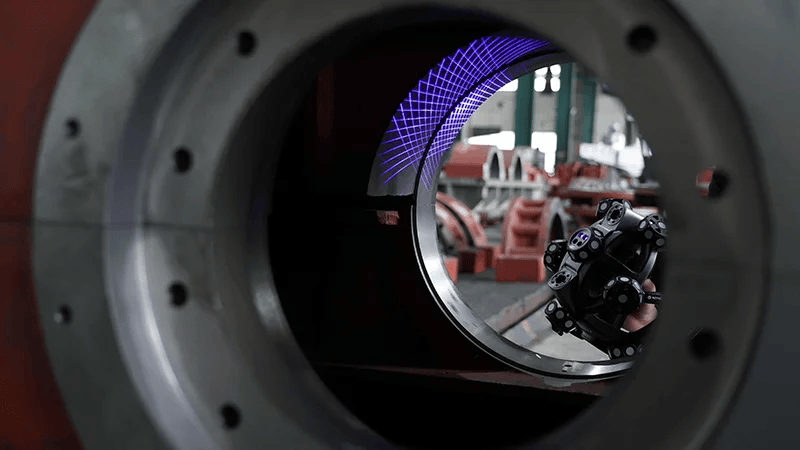

Aerospace applications demand extreme accuracy. The TrackScan 3D scanners are perfectly suited for inspecting aerospace components, including turbine blades, engine parts, and structural elements. These scanners enable dimensional verification, part alignment, and quality control, ensuring compliance with the rigorous standards of the aerospace industry.

3. Energy and Heavy Industries

For industries such as wind energy, oil and gas, and heavy manufacturing, Scantech’s 3D scanners provide precise measurements for large-scale components like turbines, piping, and structural supports. These scans are critical for maintenance scheduling, quality assurance, and performance optimization, helping companies avoid costly downtime and ensuring equipment longevity.

4. Manufacturing and Production

In manufacturing, TrackScan Series 3D scanners are invaluable for dimensional inspection and quality control. Whether it’s checking tolerances, verifying assembly accuracy, or inspecting parts for defects, these scanners help manufacturers maintain high production standards. The ability to quickly and accurately inspect parts accelerates production cycles and improves the overall quality of finished products.

5. Product Design and Prototyping

TrackScan’s precise scanning capabilities allow product designers and engineers to quickly convert physical parts into digital 3D models. This digital conversion is essential for prototyping, modification, and design iterations, enabling faster time-to-market for new products.

.png)

Why Choose Obsnap Penang?

CALL US NOW - +60124010590

EMAIL TO OUR EXPERTS - sales.penang@obsnappg.com

REQUEST A DEMO

SCANTECH TrackScan Sharp-S Optical 3D Scanning System SCANTECH TrackScan Sharp-E Optical 3D Scanning System

US 23844

US 23844  BR 19679

BR 19679  GB 14815

GB 14815  AU 9388

AU 9388  CA 8903

CA 8903  IN 5751

IN 5751  IE 5049

IE 5049  NZ 4698

NZ 4698