Please login to use this feature.

You can use this feature to add the product to your favourite list.

Close

You have removed this product from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your favourites list.

Close

This company has been removed from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your inquiry cart.

Close

This company has been added to your inquiry cart.

Close

This company has been removed from your inquiry cart.

Close

This product has been added to your inquiry cart.

Close

This product has been removed from your inquiry cart.

Close

Maximum number of Product/Company has been reached in inquiry cart.

Close

You have removed this product from your favourite list.

Close

Daily Login Reward

Congratulations!

You��ve earned your daily login reward for today!

5 NP PointHere are the reward you��ve earned!

Check your Daily Login Rewards

Be sure to come back everyday for more rewards!

Thanks!

Scan and Whatsapp Me

![qr code]() Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Business

Hours

Monday - Friday 9:00 AM - 6:00 PM

Saturday - Sunday Closed

We′re closed on

Public Holiday

Open

Closed

WINTERS Electromagnetic Flowmeter Installation - TRINITY INDUSTRIAL SOLUTION SDN BHD

WINTERS Electromagnetic Flowmeter Installation

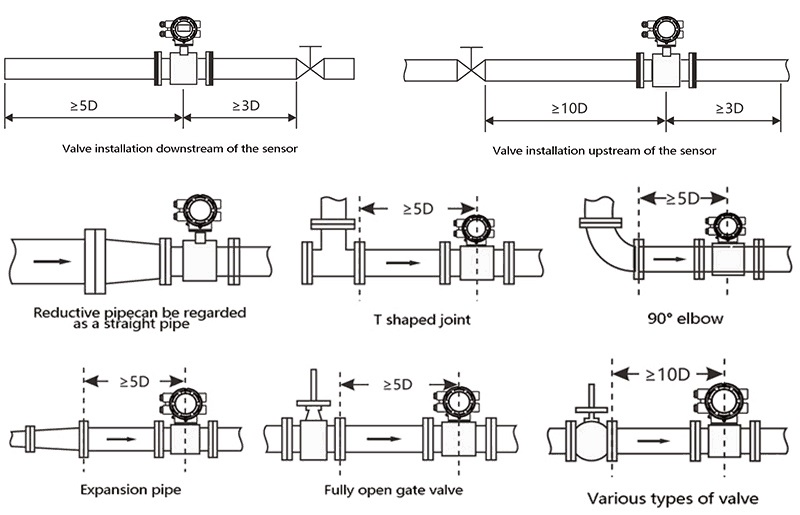

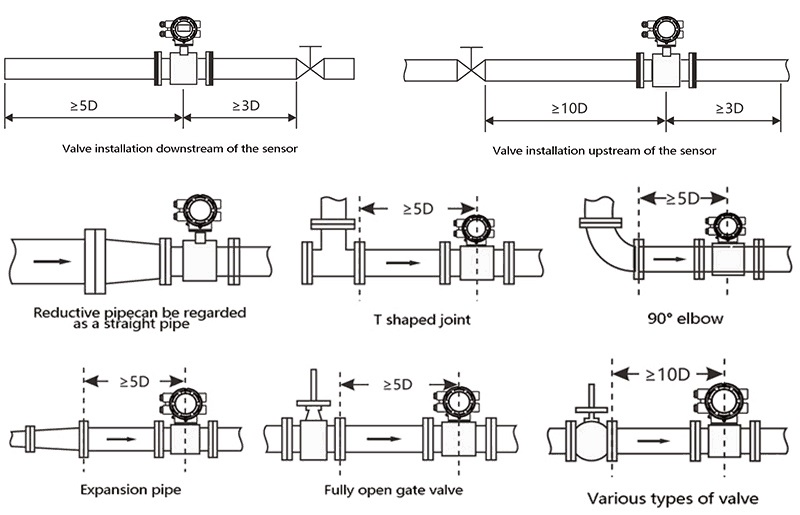

Installing an electromagnetic flowmeter correctly is essential to ensure accurate and reliable flow measurement in liquid flow applications. These flowmeters are widely used in industries such as water treatment, chemical processing, and food manufacturing due to their non-intrusive design and high precision. However, to maximize performance and avoid common installation issues, proper site selection, grounding, and piping configuration must be followed.