Please login to use this feature.

You can use this feature to add the product to your favourite list.

Close

You have removed this product from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your favourites list.

Close

This company has been removed from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your inquiry cart.

Close

This company has been added to your inquiry cart.

Close

This company has been removed from your inquiry cart.

Close

This product has been added to your inquiry cart.

Close

This product has been removed from your inquiry cart.

Close

Maximum number of Product/Company has been reached in inquiry cart.

Close

You have removed this product from your favourite list.

Close

Daily Login Reward

Congratulations!

You��ve earned your daily login reward for today!

5 NP PointHere are the reward you��ve earned!

Check your Daily Login Rewards

Be sure to come back everyday for more rewards!

Thanks!

Scan and Whatsapp Me

![qr code]() Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Business

Hours

Monday - Friday 8:30 AM - 5:30 PM

Saturday 9:00 AM - 12:30 PM

Sunday Closed

We′re closed on

Public Holiday

Open

Closed

Linear Shaft vs Linear Rails - WHEELER MECTRADE (S) PTE LTD

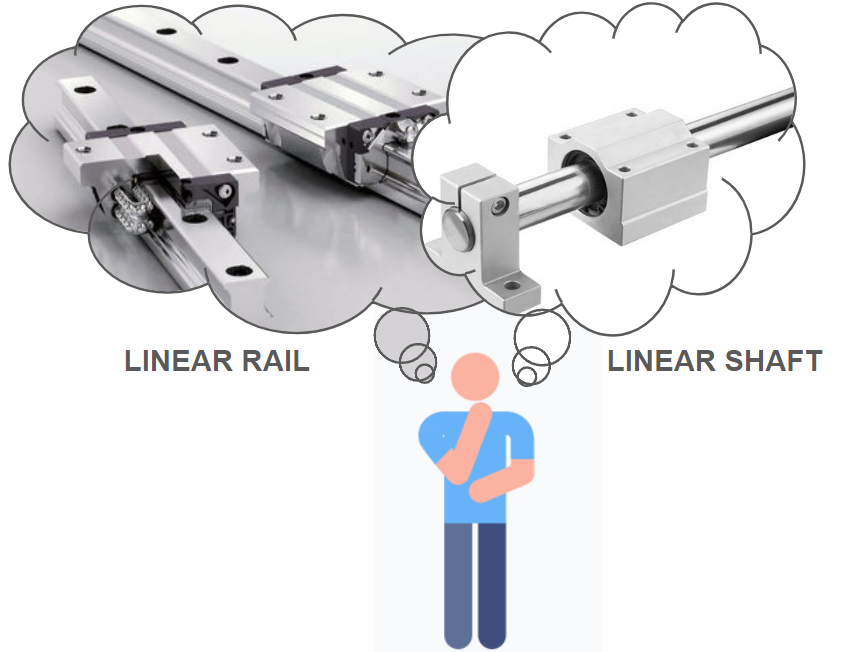

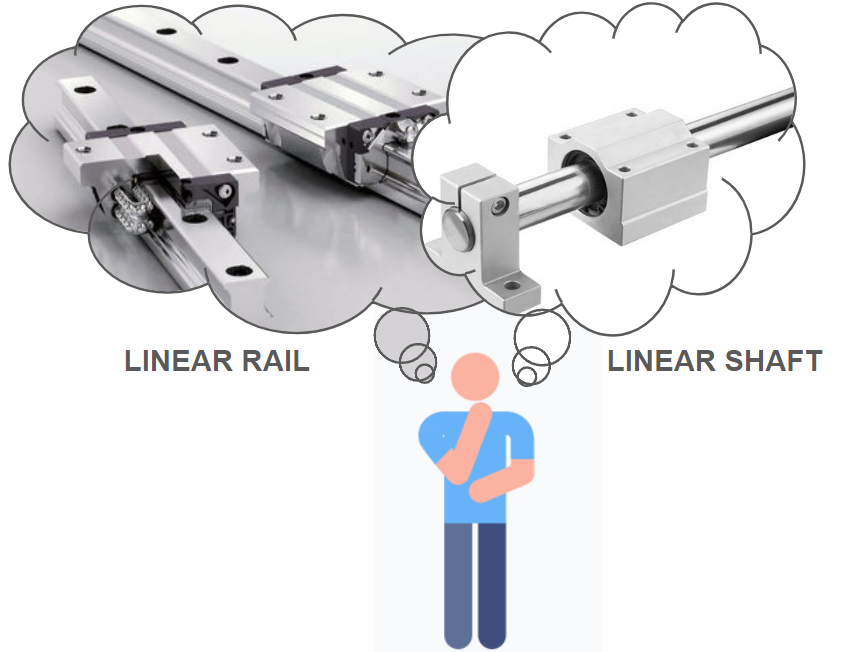

Linear Shaft vs Linear Rails

07-Dec-2023

Both linear shafts and linear rails are used for linear motion, but there are some key differences between them:

Linear shafts:

-

Simple design: A round shaft made of steel, stainless steel, or hardened chrome.

-

Lower cost: Generally cheaper than linear rails.

-

Easy to install: Can be supported by bearings or bushings.

-

Less accurate: Can bend or deflect under load, leading to less precise motion.

-

Lower load capacity: Not suitable for high-load applications.

-

Higher friction: Requires more lubrication than linear rails.

-

Limited self-alignment: Can twist or rotate under load, requiring additional components to prevent it.

Linear rails:

-

More complex design: Consists of a hardened steel rail with rolling elements like ball bearings or rollers.

-

Higher cost: More expensive than linear shafts.

-

More difficult to install: Requires precise alignment and mounting.

-

More accurate: Offers more precise and consistent motion due to its rigid design.

-

Higher load capacity: Can handle heavier loads than linear shafts.

-

Lower friction: Requires less lubrication than linear shafts.

-

Self-aligning: Some types of linear rails can self-align, compensating for minor misalignment.

Key differences:

|

Feature |

Linear shaft |

Linear rail |

|

Design |

Simple, round shaft |

Complex, with rolling elements |

|

Cost |

Lower |

Higher |

|

Installation |

Easy |

Difficult |

|

Accuracy |

Lower |

Higher |

|

Load capacity |

Lower |

Higher |

|

Friction |

Higher |

Lower |

|

Self-alignment |

Limited |

Some types |

Choosing between linear shafts and linear rails:

The best choice for your application will depend on several factors, including:

-

Required level of accuracy and precision

-

Expected load

-

Budget

-

Complexity of installation

-

Need for self-alignment

Here are some general guidelines:

-

Use linear shafts for:

-

Low-cost applications

-

Simple designs

-

Light loads

-

Non-critical applications where high accuracy is not required

-

Use linear rails for:

-

High-precision applications

-

Heavy loads

-

Complex designs

-

Applications requiring self-alignment

Here are some additional resources that you may find helpful: