Professional Guide: When to Service Your Alternator

The alternator is a critical component in any electrical system, converting mechanical energy into electrical power and ensuring batteries remain charged. Timely servicing is essential to prevent operational disruptions, costly repairs, and equipment damage. This guide provides a clear overview of the indicators and practices that determine when an alternator requires maintenance.

1. Adhere to Recommended Service Intervals

Follow the manufacturer's guidelines for maintenance. For industrial alternators, inspections are typically recommended every 3,000 to 5,000 operating hours. Scheduled servicing allows early detection of wear in bearings, brushes, and slip rings, even before performance issues appear.

2. Listen for Abnormal Noise

Noise is often the first sign of mechanical problems. Common indicators include:

- Grinding or whining sounds – may indicate bearing wear

- Squealing noises – often caused by belt misalignment or wear

- Knocking or rattling – could signify internal component damage

3. Monitor Voltage Output

Fluctuating or unstable voltage output signals potential alternator issues. Watch for:

- Low or inconsistent charging voltage

- Overcharging conditions that stress batteries

- Sudden drops in system voltage under load

4. Detect Overheating

Excessive heat reduces efficiency and shortens alternator life. Look out for:

- Burning odors

- Discolored windings

- Hot alternator casing during normal operation

5. Inspect Bearings and Vibration Levels

Worn bearings or misalignment can produce excessive vibration and noise. Indicators include shaft wobble or unusual vibration during operation. Timely maintenance prevents rotor damage and prolongs alternator life.

6. Track Battery Performance

Frequent battery failures or short lifespan may indicate charging issues with the alternator. A properly functioning alternator ensures consistent current, maximizing battery reliability and overall system performance.

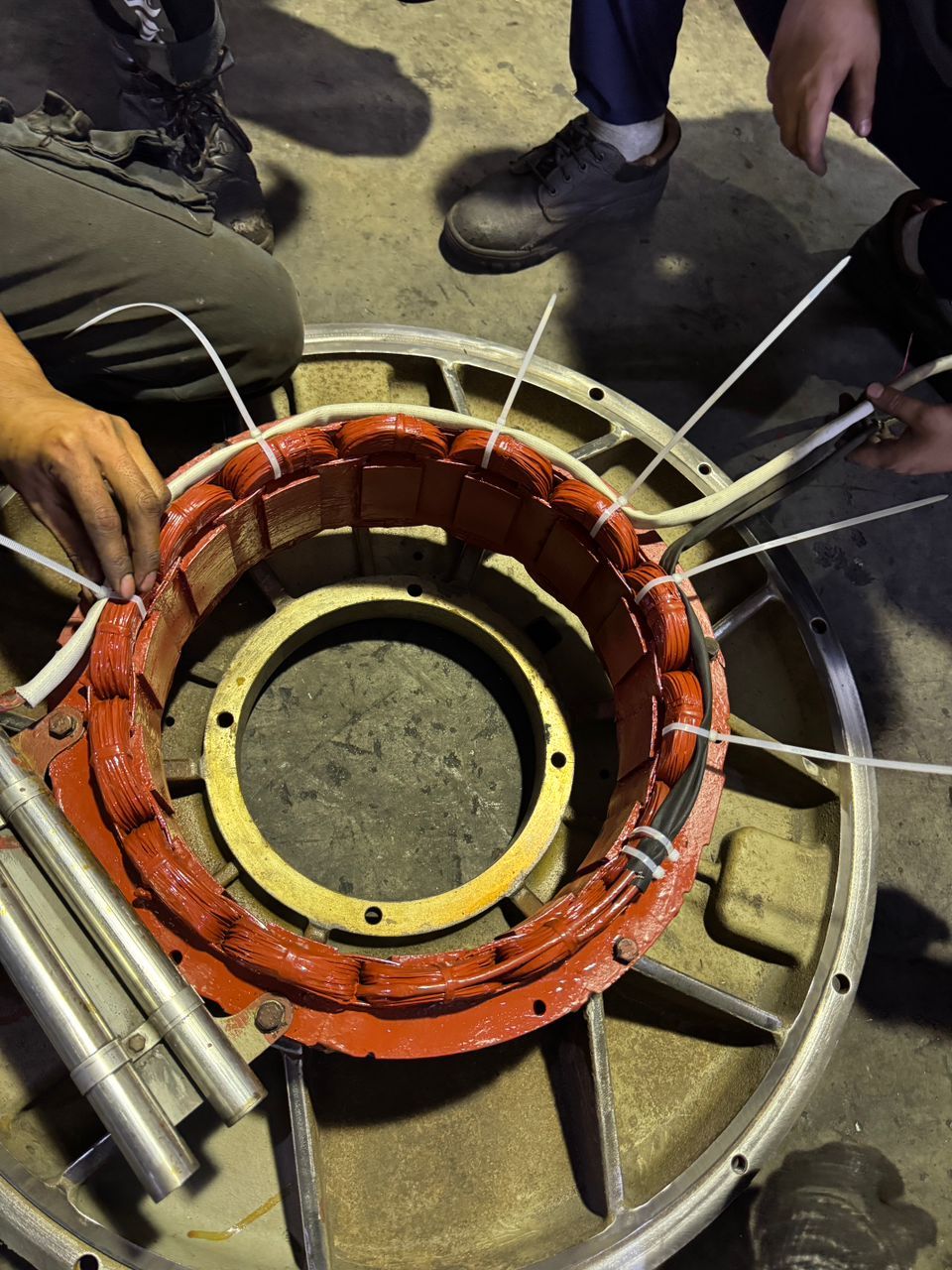

7. Conduct Visual Inspections

Routine inspections help identify physical issues such as:

- Loose or corroded terminals

- Cracked or damaged housing

- Burnt or contaminated wiring

8. Consider Operating Conditions

Harsh environments accelerate wear. Alternators operating in:

- High humidity

- Dusty or sandy conditions

- Elevated temperatures

- Heavy electrical loads

9. Pay Attention to Warning Indicators

Modern alternators often include warning lights or alarms. Never ignore these signals, as they provide early detection of charging or system faults.

10. Prioritize Preventive Maintenance

Preventive servicing is more cost-effective than reactive repairs. Regular maintenance helps identify minor issues before they escalate, reducing downtime, preventing secondary damage, and improving overall system reliability.

Conclusion

Determining the right time to service an alternator involves monitoring operating hours, voltage performance, mechanical condition, and environmental factors. Consistent preventive maintenance ensures optimal performance, extends the alternator’s lifespan, and safeguards connected equipment from unexpected failures.