Laser Alignment on Rotating Equipment

Accurate alignment is one of the most critical factors in maintaining the performance and reliability of rotating machinery. Laser alignment ensures that two or more shafts are properly positioned relative to each other, minimizing vibration, bearing wear, and energy loss.

Understanding Laser Alignment

Laser alignment is a precision method used to align the shafts of motors, pumps, compressors, fans, or other coupled machines. Unlike traditional dial indicator or straightedge methods, a laser alignment system provides fast and highly accurate readings by using laser transmitters and digital sensors to detect even the smallest misalignments.

Types of Misalignment

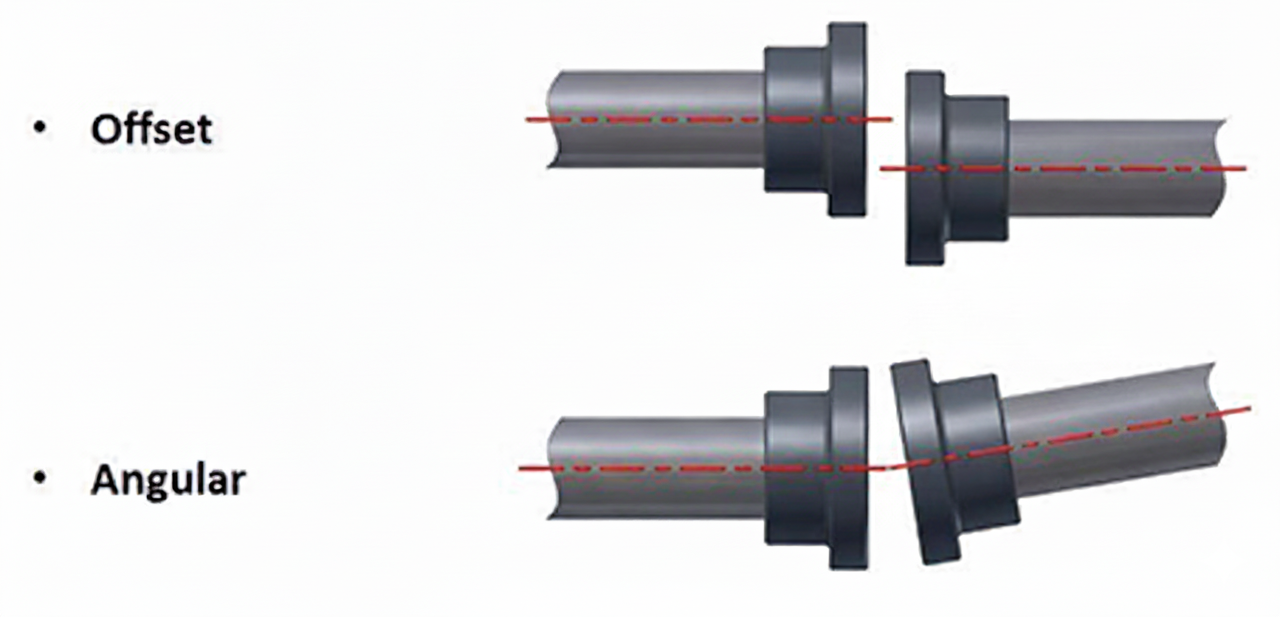

Rotating equipment typically experiences two main types of misalignment:

- Offset Misalignment: The shafts are parallel but not collinear, creating an offset between their centers.

- Angular Misalignment: The shafts are at an angle to each other, meaning they are not parallel.

Both types can occur in horizontal or vertical planes, and laser systems can detect and quantify each with precision.

Procedure of Laser Alignment

The laser alignment process generally involves the following steps:

- Preparation: Ensure both machines are mounted and bolts are tightened uniformly. Clean the coupling surfaces and check for runout or looseness.

- Setup: Attach the laser sensors and brackets to both shafts or couplings according to the manufacturer’s instructions.

- Measurement: Rotate the shafts through specified positions (usually 9, 12, and 3 o’clock) to record alignment readings.

- Adjustment: Use shims and lateral adjustments to correct horizontal and vertical misalignments as indicated by the laser display.

- Verification: After adjustments, remeasure to confirm that alignment is within the specified tolerance.

Benefits of Laser Alignment

- Reduces vibration and noise.

- Prevents premature bearing and seal failure.

- Improves energy efficiency and performance.

- Extends equipment lifespan.

- Reduces maintenance costs and downtime.

Common Applications

Laser alignment is widely used across various industries including:

- Power generation

- Cement Industry

- Palm Oil Mill

- Water treatment plants

- Steel Industry

- Manufacturing and process industries

- Oil & gas facilities

- HVAC systems

Conclusion

Proper alignment using laser technology is a key part of predictive maintenance and reliability-centered practices. By performing laser alignment on rotating equipment, companies can achieve smoother operation, reduce downtime, and ensure optimal performance of their machinery.

BR 35722

BR 35722  US 12813

US 12813  VN 5374

VN 5374  MY 4181

MY 4181  MX 3138

MX 3138  AR 2909

AR 2909  GB 2531

GB 2531  CN 1784

CN 1784