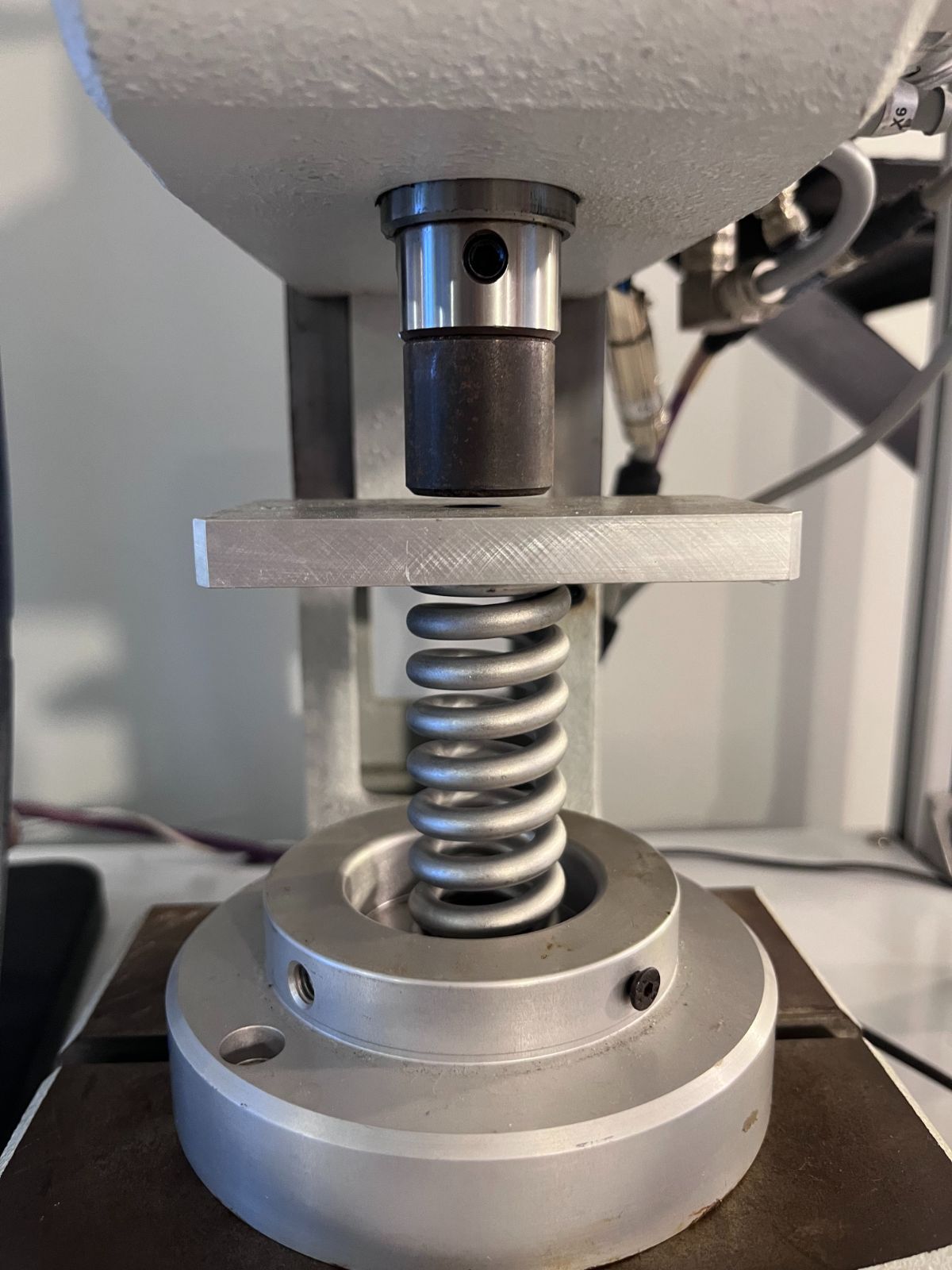

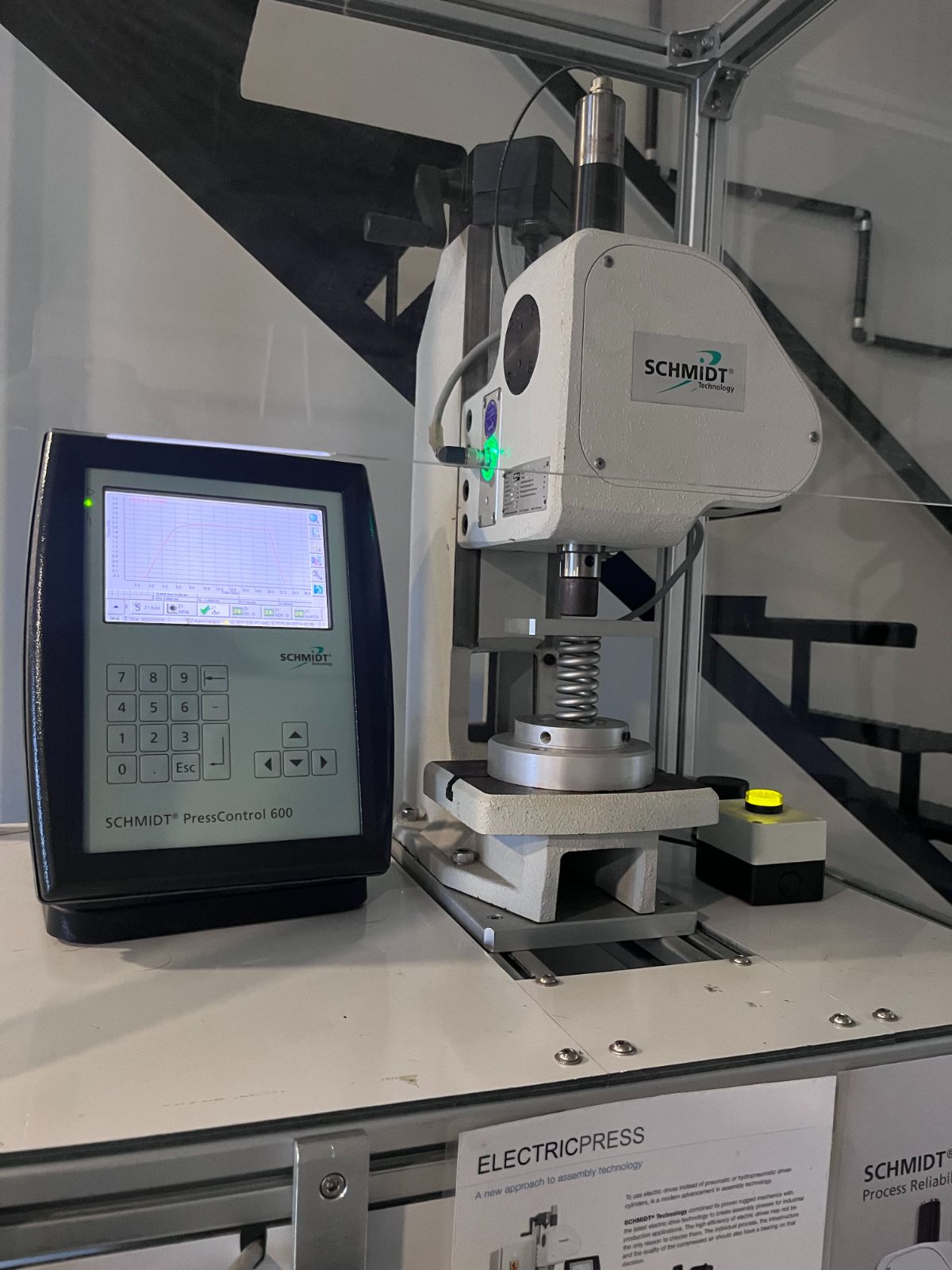

That’s why we’ve integrated the SCHMIDT Electric Press into our spring force testing process to deliver highly accurate, real-time compression data.

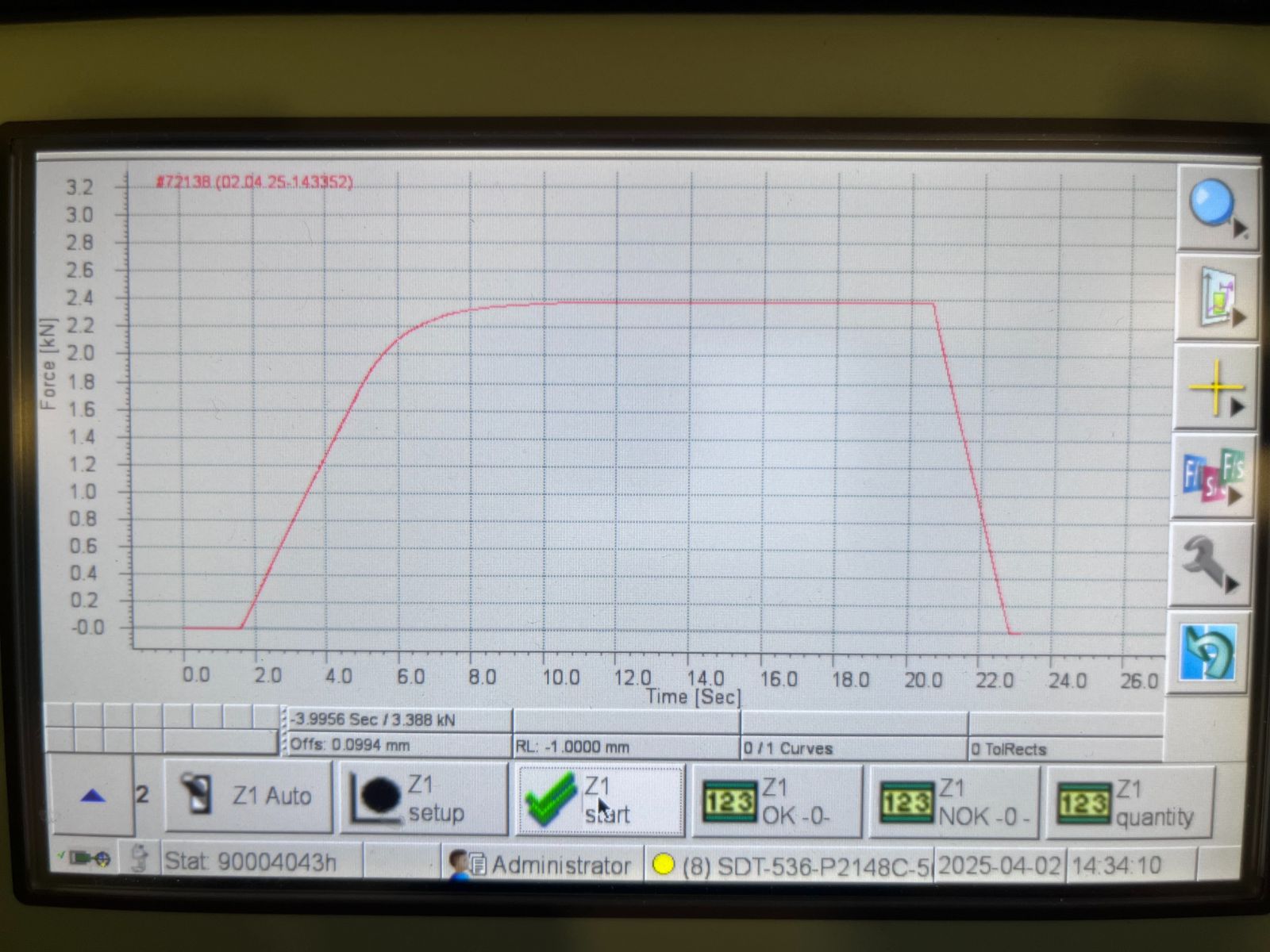

Using this advanced system, we can apply a controlled load to compression springs and capture the force profile throughout the compression cycle. This capability allows us to define spring characteristics such as load tolerance, deflection rate, and overall performance with exceptional repeatability and accuracy.

For applications where safety, performance, and reliability are non-negotiable—such as suspension systems, actuators, and control assemblies—this testing method helps validate component integrity before deployment.

Whether you're designing components for high-speed automotive systems or mission-critical aerospace mechanisms, our spring compression testing ensures your parts perform exactly as intended under load.

Key Benefits:

- Real-time force monitoring

- High repeatability and precision

- Ideal for high-spec engineering environments

- Supports strict compliance standards

To learn more about how our testing solutions can support your next project, get in touch with our engineering team or visit our lab for a demonstration.

Full video at our YouTube channel.