PTC is a semiconductor ceramic component with a positive temperature coefficient. Its main representative materials are barium titanate series. It is an organic compound. It is made into heating elements of various shapes and specifications through molding and high-temperature sintering. When the PTC component is used, as long as an AC or DC power supply is added to the two ends of the piece, the rated heating temperature can be obtained.

2. Characteristics of PTC

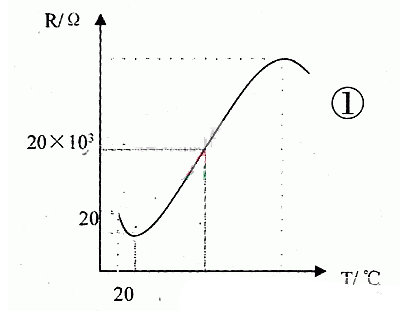

Take barium titanate semiconductor ceramics as an example, the relationship curve between its temperature and resistivity is shown in Figure 1. When the temperature is below 100°C, it presents ordinary semiconductor characteristics. That is, when the conductor temperature rises from a certain value from the beginning, the resistance decreases, which is a negative temperature coefficient. When the temperature rises to a range above 100°C, its resistance rises sharply by several orders of magnitude as the temperature rises. It presents a strong positive temperature coefficient characteristic. The starting temperature of this positive temperature coefficient characteristic is called the Curie temperature, represented by tp, and the above-mentioned abnormal impedance change phenomenon is called the PTC characteristic. In the actual production process of PTC components, the Curie temperature can also be changed by differences in production process and added materials. For example, if strontium (SR) and tin (Sn) are added, the Curie temperature moves toward low temperature; if lead (Pb) is added, the Curie temperature moves toward high temperature. At present, the Curie temperature of PTC is generally controlled and selected within -20 to 300°C.

3. Application examples of PTC electric heating elements

1)The electric heating element in the PTC constant temperature electric iron is a PTC element, which is composed of 10 PTC elements in parallel. Because of the use of PTC electric heating elements, the outstanding advantages of this electric iron are: using the characteristics of the PTC element, the electric heating element itself has an automatic temperature control function: because the resistance of the PTC element is only related to the temperature, it is less affected by the fluctuation of the power supply voltage; it is safe and reliable to use, and has a long working life.

2)PTC automatic constant temperature electric rice cooker Since the PTC element replaces the bimetallic constant temperature control switch in the automatic constant temperature electric rice cooker, the positive temperature coefficient characteristics of the PTC element are used to control the current flowing through the heater during the insulation process of the electric rice cooker, which is more convenient to achieve constant temperature control of the electric rice cooker. The outstanding feature of this rice cooker is the high precision of constant temperature control. It has a long service life.

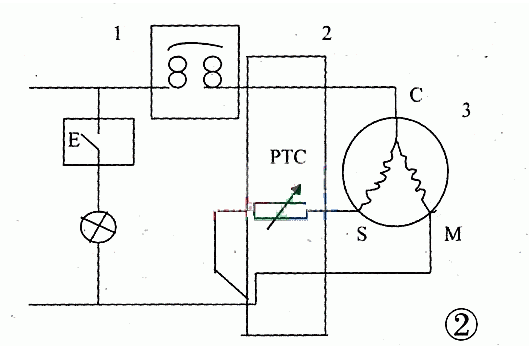

3)PTC starting relay To ensure the normal starting and safe operation of the refrigeration compressor motor, refrigerators are equipped with starting and protection devices. The PTC starting relay is a device that controls the connection and disconnection of the motor starting winding and power supply, as shown in Figure 2. The starting relay is a contactless switch. When the refrigerator starts, the temperature of the PTC element is lower than the Curie temperature and the resistance value is small. Generally, it is only about 20Ω. At this time, the PTC element is in the "open" state, which is equivalent to the relay being closed. During the starting process, because the current is 4 to 6 times greater than the normal working current, the temperature of the PTC element rises sharply due to the thermal effect of the current. When the temperature rises above the Curie temperature, it enters a high resistance state. The PTC element is actually in the "off" state. At this time, the current is sharply reduced to a stable current of 10~20mA, making the starting winding circuit almost open. This type of starter has the advantages of no contact arc, no noise, reliable starting performance, strong adaptability to voltage fluctuations, wide matching range for compressors, etc. It also has the characteristics of small size, firm structure, vibration resistance, impact resistance, easy installation, and long service life. Because its on and off performance depends on its own temperature change. Therefore, the refrigerator cannot be started immediately after it stops. It must wait until its temperature drops below the critical point before it can be restarted. The time interval between two starts needs 3 to 5 minutes, otherwise, the PTC is still in a state close to high resistance. The starting winding cannot start the motor because there is not enough current flowing through it. However, a large current passes through the running winding, causing the motor to heat up and easily damage the motor. In addition, the PTC element itself consumes about 4w of power, so after the circuit is connected in series with the PTC element, the power consumption of the refrigerator will increase.

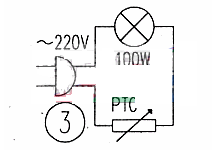

4)Judgment and treatment of the quality of the PTC starter. Method to judge whether the PTC starter is good or bad: connect the PTC starter according to the circuit shown in Figure 3, insert the power plug into the 220V AC power socket, the light will be on within 1~2s, and the light will dim until it goes out after 10~15s, which means the PTC starter is good. If the light does not light up after power on or the light keeps on, it means that the PTC starter is broken or has lost its control function. In order to determine the correctness of the above judgment, the PTC starter can be disconnected from the power supply, cooled for 3 minutes, and then plugged into the power supply, and the above phenomenon should be repeated. If checked with a multimeter, the resistance of the PTC starter is measured at room temperature (about 25��) with the R×1 gear. The resistance range is 10~50n, which is normal. If it is heated, the resistance of the PTC starter should gradually increase with the increase of temperature. It is also normal. After the PTC starter is damp, its resistance drops rapidly, and it can be placed in an oven for drying. The temperature of the oven is controlled at 140~150�� for about 3 hours. If the PTC starter is damaged, it is because the working current exceeds its rated current, causing the PTC to heat up and break. In this case, the only way is to replace the PTC starter.