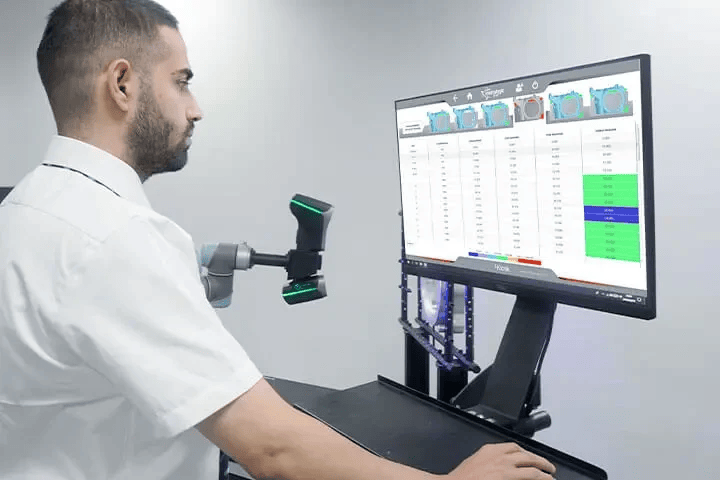

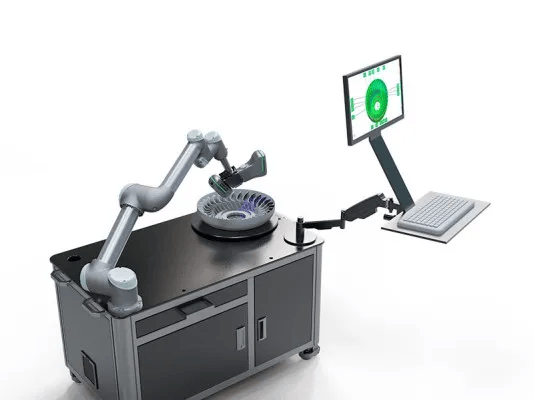

The AutoScan-K 3D System by Scanology is an advanced automated 3D scanning solution designed for high-precision, non-contact, and non-destructive 3D measurement applications. Leveraging cutting-edge machine vision technology, this 3D system ensures exceptional accuracy while facilitating efficient online batch scanning and inspection processes. Operating continuously 24/7, the AutoScan-K 3D system significantly reduces manufacturing costs, accelerates time-to-market, and enhances return on investment for enterprises.

Applications

The AutoScan-K 3D system is ideal for various industries requiring precise 3D measurements, including:

Aerospace: For scanning and inspecting complex aerospace components.

Automotive: Ensuring quality control and precision in automotive parts.

Mold Manufacturing: Verifying mold dimensions and integrity.

Energy & Heavy Industry: Conducting inspections of large and heavy industrial components.

Railway & Shipbuilding: Monitoring structural elements and assemblies.

Features – Scanology AutoScan-K 3D System

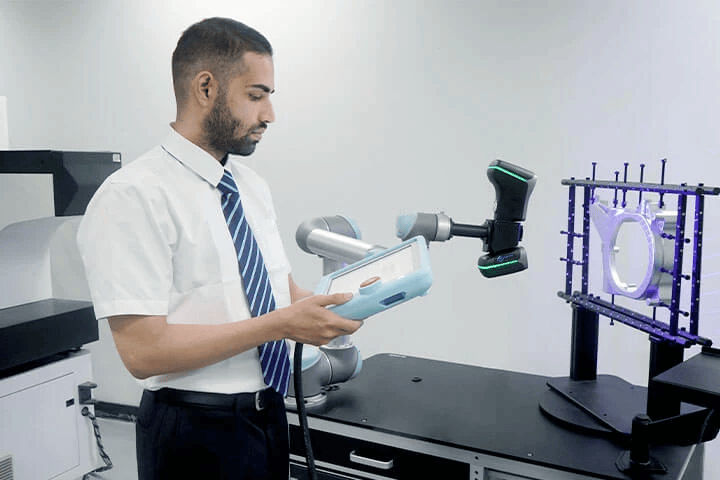

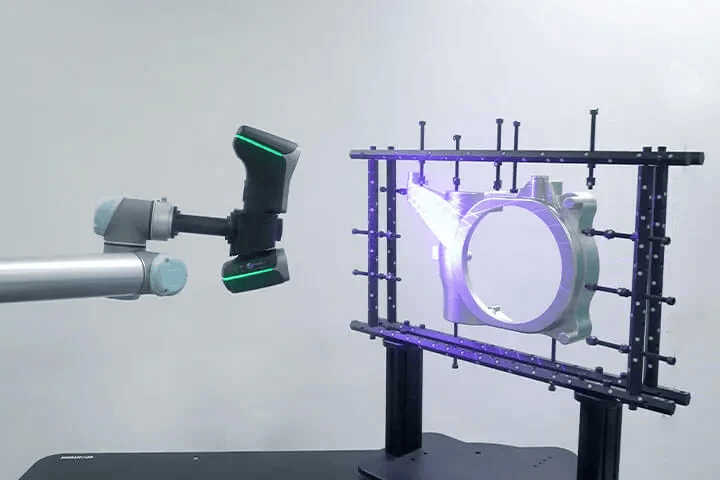

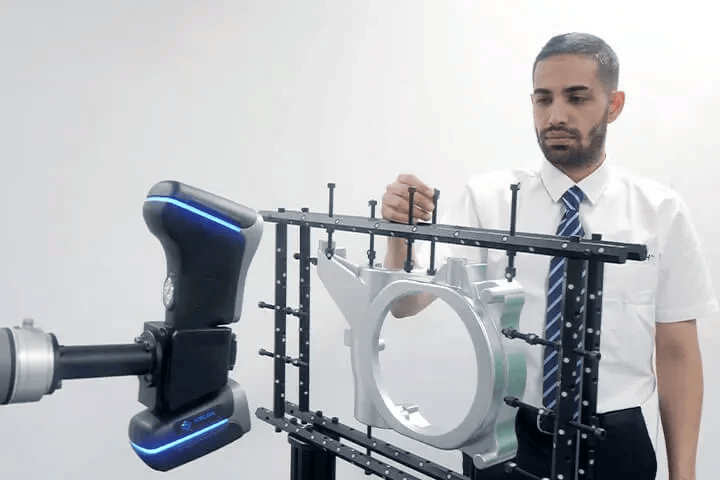

1. Fully Automated 3D System

The AutoScan-K 3D system adapts to various workpiece sizes with programmable paths, ideal for dynamic and high-mix production environments using a reliable 3D scanner.

The AutoScan-K 3D system captures up to 4.15 million measurements per second, with accuracy up to 0.020 mm, making it a top-tier industrial 3D scanner for precision applications.

This 3D system supports secondary development and SDK integration, making it highly compatible for industrial automation and smart 3D measurement systems.

Technical Specifications

| Type | AutoScan-KM II | AutoScan-KM | |

| Ultra-fast scanning | 17 blue laser crosses | 11 blue laser crosses | |

| Scan mode | Hyperfine scanning | 7 blue parallel laser lines | |

| Large area scanning | 11 parallel infrared laser lines | ||

| Deep hole scanning | 1 extra blue laser line | ||

| Accuracy(1) | Up to 0.020 mm (0.0008 in) | ||

| Scanning rate up to | 4,150,000 measurements/s | 2,700,000 measurements/s | |

| Scanning area up to | 1440 mm × 860 mm (57.0 in × 33.9 in) |

||

| Laser class | CLASS �� (eye-safe) | ||

| Resolution up to | 0.010 mm (0.0004 in) | ||

Photogrammetry system |

Scanning area | 3760 mm × 3150mm (148.0 in × 124.0 in) |

|

| Depth of field | 2500 mm (98.4 in) | ||

| Work alone | 0.015 mm + 0.030 mm/m (0.0006 in + 0.00036 in/ft) |

||

| Volumetric accuracy(2) | Work with 1 m reference bar | 0.015 mm + 0.020 mm/m (0.0006 in + 0.00024 in/ft) |

|

| Work with MSCAN-L15 | 0.015 mm + 0.012 mm/m (0.0006 in + 0.00014 in/ft) |

||

| Stand-off distance | 300 mm (11.8 in) | ||

| Depth of field | 925 mm (36.4 in) | ||

| Output formats | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. | ||

| Operating temperature range | -10��-40�� (14! -104! ) | ||

| Interface mode | USB 3.0 | ||

Patents |

CN204329903U, CN104501740B, CN104165600B, CN204988183U, CN204854633U, CN204944431U, CN204902788U, CN105068384B, CN105049664B, CN204902784U, CN204963812U, CN204902785U, CN204902790U, CN106403845B, CN209197685U, CN209263911U, CN106500627B, CN106500628B, CN206132003U, CN206905709U, CN107202554B, CN209310754U, CN209485295U, CN209485271U, CN305446920S, CN209991946U, US10309770B2, KR102096806B1, KR102209255B1, US10914576B2 | ||

(1) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, probing error (size) (PS) performance is evaluated.

(2) ISO 17025 accredited: Based on VDI/VDE 2634 Part3 standard and JJF 1951 specification, sphere spacing error (SD) performance is evaluated.