Upgrade Vehicle Modification Workflows with Advanced 3D Scanning Solutions

by OBSNAP PENANG

The automotive and vehicle customization industry is experiencing rapid growth. From performance upgrades to aesthetic modifications, precision and efficiency are critical at every stage of the vehicle modification process. Traditional measurement tools and manual workflows often fall short in terms of accuracy, speed, and repeatability, leading to longer project timelines, increased costs, and potential errors.

To address these challenges, Obsnap Instruments (Penang) provides advanced 3D scanning solutions that streamline vehicle modification workflows, enabling manufacturers, workshops, and designers to achieve superior results with precision and confidence.

The Challenges in Vehicle Modification

Vehicle modification and custom upgrades involve complex tasks such as:

-

Fitting aftermarket parts and body kits

-

Customizing interiors and components

-

Ensuring precise alignment for performance enhancements

-

Reverse engineering existing parts for upgrades

-

Fabricating replacement or unique components

Traditional methods rely heavily on manual measurements, templates, and trial-and-error, which can be time-consuming, error-prone, and costly. Achieving perfect alignment and fitment often requires multiple iterations, delaying project timelines and increasing production costs.

How Advanced 3D Solutions Transform Workflows

By integrating high-precision 3D scanning and inspection technology, Obsnap Instruments enables automotive professionals to:

1. Capture Accurate Digital Models

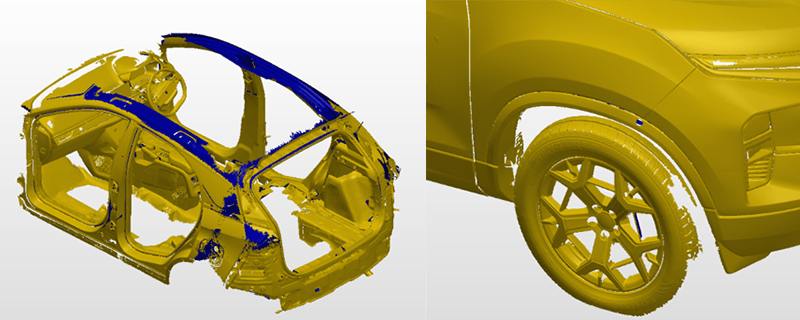

Advanced 3D scanners capture complete surface data of vehicles, components, or assemblies, creating highly detailed digital models. These models are crucial for evaluating modifications, testing fitment, and ensuring compatibility before any physical adjustments.

2. Streamline Reverse Engineering

For custom or discontinued parts, 3D scanning allows engineers to create precise digital replicas, enabling fabrication, modification, or redesign without original CAD drawings.

3. Improve Fitment and Alignment

Using accurate 3D data, body kits, panels, and aftermarket components can be precisely aligned, reducing errors and rework. Modifications can be tested virtually before installation, saving time and materials.

4. Enhance Collaboration

Digital models can be easily shared with designers, fabricators, and engineers, improving communication, reducing mistakes, and accelerating approval workflows.

5. Integrate with CAD/CAM and Inspection Software

The captured 3D data can seamlessly integrate with CAD/CAM systems, enabling:

-

Simulations of modifications

-

Performance analysis

-

Automated inspection for quality assurance

Recommended 3D Scanning Solutions for Vehicle Modification

Obsnap Instruments (Penang) offers a range of industry-leading scanners ideal for automotive modification workflows:

-

KSCAN-Magic Series – High-speed scanning with ultra-fine detail for small to large components

-

TrackScan-Sharp – Marker-free optical tracking for full vehicle assemblies

-

NimbleTrack – Portable and dynamic scanning for real-time modification analysis

-

SIMSCAN – Compact scanners for daily QC and design verification

These systems enable fast, accurate, and non-contact scanning, making them ideal for workshops, design studios, and automotive manufacturers looking to optimize modification workflows.

Why Choose Obsnap Instruments (Penang)?

-

On-site and workshop-friendly scanning services

-

Trained engineers for setup, operation, and data analysis

-

Tailored solutions for vehicle modification, prototyping, and inspection

-

Local support for seamless integration and maintenance

By adopting 3D scanning technology, automotive professionals can reduce errors, accelerate modification processes, and deliver high-quality results consistently.

Conclusion

Advanced 3D scanning is transforming vehicle modification workflows, enabling workshops, manufacturers, and designers to achieve precision, efficiency, and superior quality. With Obsnap Instruments (Penang) and Scantech’s 3D solutions, every modification, upgrade, or custom fabrication project can be planned, tested, and executed digitally, reducing downtime, costs, and rework.

Contact Obsnap Instruments (Penang) today to discover how our 3D scanning

solutions can upgrade your vehicle modification workflows and accelerate your

automotive projects.

Contact: 012-4010 590 (Mr.Alex) Email : sales.penang@obsnap.com

Website: www.obsnappg.com

#3DScanning #VehicleModification #ReverseEngineering #ObsnapInstruments #AutomotiveInnovation #PrecisionEngineering #CAD #3DInspection #Metrology #PenangIndustry