Efficient energy conversion, reduce power consumption. No need water for hydraulic oil cooling.

Efficient

Synchronous machine movement is possible to achieva short cycle time with high precision

Precise

Up to 0.01 mm high position control accuracy, ensure product quality

Clean

No pressure hydraulic oil, keep a clean production environment

High Speed

High-speed & smart movement control for mold and injection, fulfill different application

Quiet

Low noise level, create comfortable environment

- Fast & close loop control system excellent repeatability performance

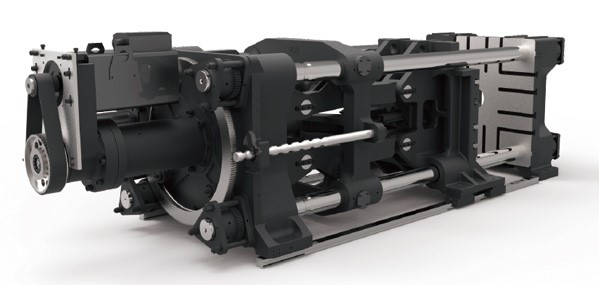

- Patented central clamping toggle system create uniform clamping force. reduces platen deflection

- Platen drive by servo motor and ball screw.

- German design of plasticizing system increase efficiency of plasticizing over 20%

- Patented encapsulated ball screw

Description

Drive System

E-version Of Central Clamping Toggle System

.jpg)

Saving

Save material

Save eletricity

Save nr. of machine

Save maintenance

Precise

Precise position

Precise Speed

Realible mold protection

Precise parallelsim

Large

Large space between tie-bars

Large open stroke

Save material

Save eletricity

Save nr. of machine

Save maintenance

Precise

Precise position

Precise Speed

Realible mold protection

Precise parallelsim

Large

Large space between tie-bars

Large open stroke

Clean

The product area is free of oil

The product area is free of oil

.jpg)

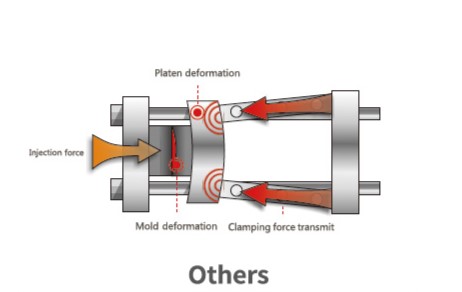

BOLE centre clamping structure

- 100% clamping force effiency

- 2-5 % material saving

- Reduces mold wear, platen deflection

- Less possibility of flash, save flash trim work

Traditional Toggle System

- 80-85% clamping force efficiency

- Moving platen with obvious deformation, cause flashes, waste of material and labor of trim the flashes.

Central Clamping Toggle System Driven By Servo Motor & Ball Screw

- Precise control for mold movement, repeatability up to 0.1mm, fit for IML or automation

- Flexible control curve, smooth and fast mold movement

- Sensitive mold pretention function

Platen Supported by Linear Guide .jpg)

.jpg)

- High platen parellelism

- No lubrication on movable platen

- Keep clean around part-drop-area

Patented Encapsulated Ball Screw Structure

Tradition

- Traditional design of ball screw structure is open to air, dust will be stick on the ball screw surface.

- Friction will increase ball screw temperature

- Lubrication condition become worse

Breakthrough

- Encapsulated ball screw, reduce the requirement of workshop environment

- The heat created by friction is taken by oil bath, Ballscrew is well kept cool.

- Lubrication is kept on the friction surface by oil path.

Patented Encapsulated Ball Screw Structure

- Take away friction heat rapidly, reduce ball screw temperature and abrasion

- Obstruct dust pollution, request of using environment is low.

- Expensive and important ball screw lubrication grease is unnecessary.

- More easy for maintenance, no need to clean fatlute.

Control Technology

.jpg)

- Integrated with the accuracy control software of Mold Opening Positioning, the mold open-close positioning accuracy of injection moulding machine can reach ±0.5mm.

- Integrated with the patented control software for Intelligent Injection Process Compensation, the repeated accuracy of final product can be less than 0.3%.

- Equipped with I/O safety advice against short circuit.

- Main electic component use brand Schneider Eaton, ABB, Fuji, which ensure long service life.

- Independent Strong and weak wire layout, high anti interference, Independent electric control box structure, convenient for installation, examination and repair.

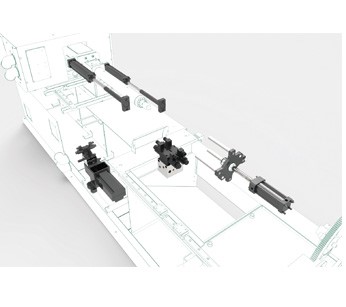

Embedded Servo Hydraulic Pump Station

- Symmetrical cylinder arrangement for injection career, offer reliable and balance nozzle contact.

- Servo drive hydraulic pump station, power saving and effectively

- Hydraulic ejector and core puller flexible to meet different mold requirement

- Option for full electricity version: without hydraulic pump station and corepull, electrical drive for carrier movement and ejector.