Our solutions are designed revolving around YOUR needs and requirements. No factor is out of the equation.

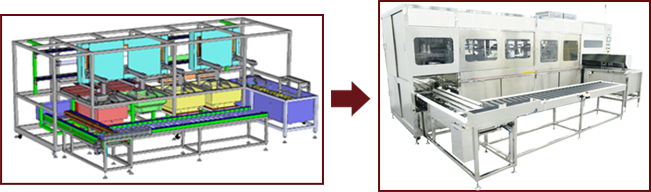

Standard

We Manufacturer from Simple Single Ultrasonic Tank:

Custom

Due to the ever changing nature of the specific precission cleaning manufacturing process, we have at our disposal a team of very experienced and innovative engineers and designers from a wide variety of back-ground to cater to your every need.

- ULTRASONIC AQUOES BASE CLEANNER

- SPRAY WASH CLEANNER

- HIGH PRESSURE JET WASHER

- HYDROCARBON BASE CLEANNER

- HYDROCARBON RECYCLE SYSTEM (RECYLING)

- SOLVENT BASE CLEANNER (HFE, HCFC, TCE & etc.)

- SEMI AQUOES BASE CLEANNER

- CONVEYOR CLEANNER

- MULTI ARM ULTRASONIC CLEANING MACHINE

- SINGLE ARM ULTRASONIC CLEANING MACHINE

- REEL TO REEL ULTRASONIC CLEANING MACHINE

State of The Art

Cleaning method: Ultrasonic, Jet Spray, Brush, Shower, Spray, Agitate, Bubbling, Circulation, Rotating, Jet FLow, vacuum ultrasonic and etc.

Rinsing method: pump overflow, 4 sided over flow, agitation, degassing system, closed system, still, effulent treatment, steam and etc.

Drying method: Vacuum, DI water slow pull, suction, spine, hot air, water separate (HFC, HFE, IPA, HCFC), vapor drying (HC, HFC, HFE, IPA, HCFC), Air Knife, Infared ray, radio wave and etc.

Suitable for Plastic injection part, Casting part, Aircraft Component, Aerospace Manufacturing, Maintainance Part, Glass, Aluminium and other engineering parts.

Can your company keep up? The true cost of innovation and its effect on your bottom line.

Please contact us for South East Asia Market, Malaysia, Vietnam, Indonesia, Thailand, Philippines, Singapore, Brunei, Laos, Myanmar and Australia for more information.