Design, Fabrication & Installation of 46 kVA John Deere Acoustic Canopies.

Projects: Berantai East, Irong Timur & Kurma Manis

Client: Vestigo Petroleum Sdn Bhd

Main EPC: Malaysia Marine & Heavy Engineering (MMHE)

Scope by ISTIQ: Acoustic Canopy Design, Fabrication, Testing & Commissioning

Vestigo Petroleum Sdn Bhd, a subsidiary of PETRONAS, is entrusted with developing and rejuvenating Malaysia’s marginal and mature offshore oil and gas fields. Among its current developments are the Berantai East, Irong Timur, and Kurma Manis platforms, each requiring dependable auxiliary power generation to support essential offshore operations. These wellhead platforms follow a compact, efficient development philosophy and therefore depend on robust, low-maintenance generator systems capable of meeting strict offshore noise and safety requirements.

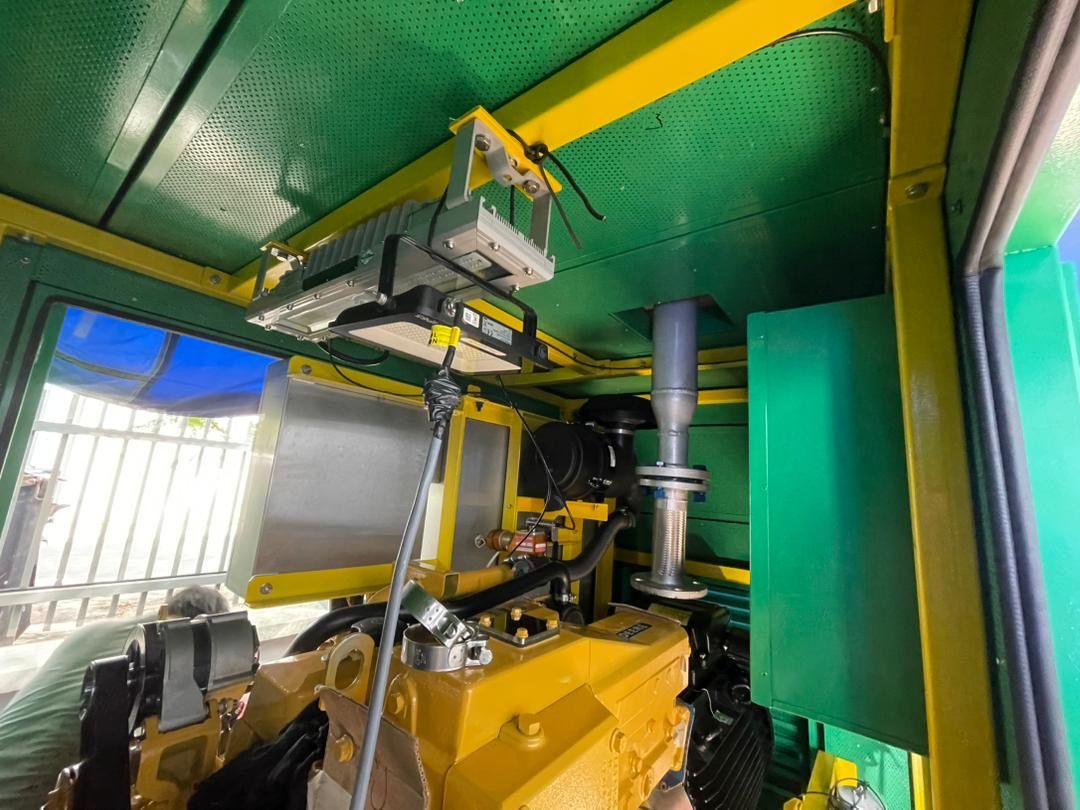

To support these field developments, ISTIQ Noise Control Sdn Bhd was appointed to deliver complete 46 kVA John Deere Diesel Engine Generator (DEG) packages. Each unit was supplied with a fully engineered acoustic canopy designed to ensure durability in offshore conditions as well as compliance with Vestigo’s noise control requirements. The canopy design incorporates high-performance insulation, engineered airflow paths for intake and discharge, an offshore-rated exhaust silencer system, weather-resistant construction, and proper access points for safe, efficient maintenance.

As part of the project delivery, detailed acoustic performance tests were performed during the Factory Acceptance Test (FAT). Noise measurements were taken around the generator using both ISTIQ’s standard instruments and a newly tested Svantek sound level meter for verification. The results confirmed an average internal genset noise of about 100.1 dBA and an average of 79.6 dBA at a distance of one metre from the canopy, representing a noise reduction of approximately 20.5 dBA. These results met and exceeded the client's acceptance criteria, validating the acoustic design's effectiveness.

Beyond fabrication, ISTIQ also provided full installation, integration, and commissioning support, ensuring seamless interface with the EPC and platform systems. All work was executed in accordance with offshore standards, including structural integrity, hot surface safety, ventilation, and corrosion protection. The successful completion of this project across three offshore platforms demonstrates ISTIQ’s capability to deliver reliable and compliant acoustic canopies and noise control solutions for the oil and gas sector, strengthening our track record in offshore power generation noise management and proving our readiness to support similar developments in the future

BR 29003

BR 29003  VN 10771

VN 10771  US 9383

US 9383  IN 5719

IN 5719  AR 4637

AR 4637  MX 3553

MX 3553  BD 2820

BD 2820  PK 2591

PK 2591