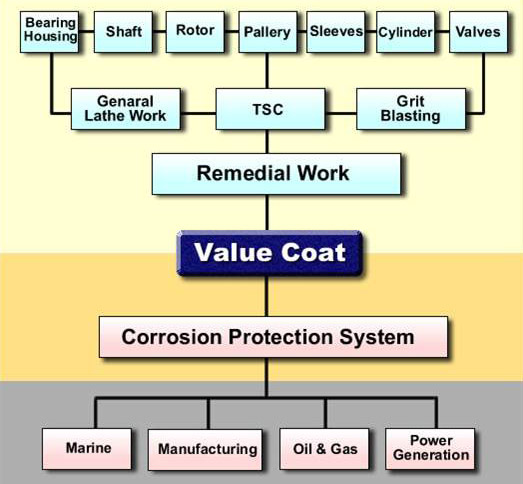

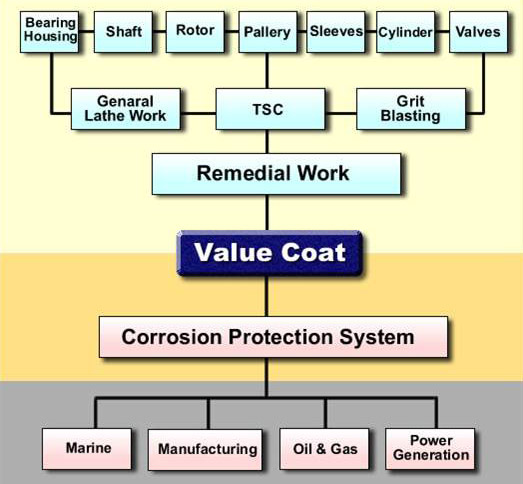

We are a Machining Company with major specialization in Termal Sprayed Coating Technology. We also provide the following auxiliary services: sand blasting, general lathe work, milling work, cylinder grinding, welding etc.

Thermal Sprayed Coating is a unique technology that spread a thin layer of strong metal coating upon the surface of mechanical part with good bonding property. The metal coating is strongly bonded upon the surface of the mechanical parts will restore the diameter/ width to its ORIGINAL MEASUREMENT size.

This restoration is required for optimum functionality of the mechinical part as it has little tolerance for diameter size change. This is especially true for high speed mechanical part, eg. Bearing housing, valve pulley, sleeve etc.

2 factors that cause the reduction of the diameter/ width size of metal part:

1) Constant wear and tear

2) Corrosive environment

Without this remedial work the mechanical part will be scrapped and immediate replacement can’t be avoided.

Restoration will cost a fraction of the total replacement cost.

**Call us for our professional service. We may help to save your maintenance cost & time taken up to 95%

Value Coat contributes positive solutions to the maintenance sector in industries through the following:

Thermal spraying

Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The “feedstock” (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame).

Thermal spraying can provide thick coatings (approx. thickness range is 20 micrometers to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals, alloys, ceramics, plastics and composites.

They are fed in powder or wine form, heated to a molten or semi molten state and accelerated towards substrates in the form of micrometer-size particles. Combustion or electrical arc discharge is usually used as the source of energy for thermal spraying. Resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significantly, allowing the coating of flammable substances.

We Specialize In:

Remedial Work

Thermal Sprayed Coating Technology

Corrosion Protection System

General Lathe , Milling & Grinding Work

Fabrication & Modification Work

Sand Blasting

Mechanical & Welding Works

Refurbishing & Repair Works

Thermal Sprayed Coating Technology

Corrosion Protection System

General Lathe , Milling & Grinding Work

Fabrication & Modification Work

Sand Blasting

Mechanical & Welding Works

Refurbishing & Repair Works