Cleanroom Filtration & Clean Bench Systems in Malaysia

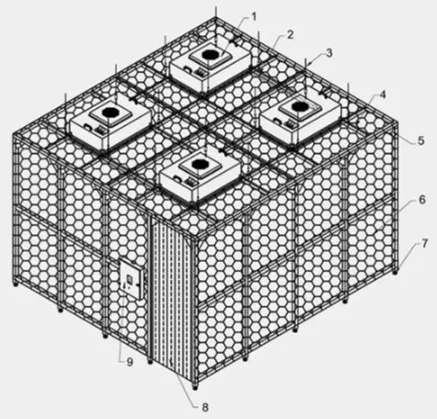

Maintaining a contamination-free environment is critical for every cleanroom operation. At EEPS Engineering Sdn Bhd, we provide advanced Cleanroom Filtration Systems in Malaysia, including Clean Benches, Fan Filter Units (FFU), and HEPA/ULPA filters. Our solutions are engineered to deliver uniform laminar airflow, effectively capture microscopic airborne particles, and comply with international cleanroom standards such as ISO 14644-1. These filtration systems play a vital role in protecting sensitive processes and ensuring operational reliability in controlled environments.

Our cleanroom filtration and clean bench systems are widely trusted by industries such as pharmaceuticals, semiconductors, electronics, medical devices, and biotechnology, where air quality, sterility, and particle control are non-negotiable. By integrating high-quality filtration technology with robust structural design, EEPS Engineering helps businesses maintain cleanroom integrity, enhance productivity, and meet regulatory requirements.

Key Features of Our Cleanroom Filtration Systems

Parameter

-

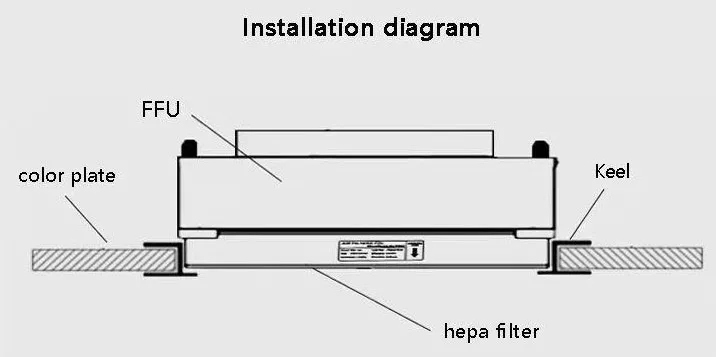

FFU (Fan Filter Unit) for consistent airflow and particle control

-

LED Lighting (36W) for clear visibility in clean environments

-

Ceiling Device (where necessary) for structured air distribution

-

Framework Options: Cold-rolled steel (powder-coated), aluminum, or stainless steel

-

Iron Indices for structural durability

-

Wall & Ceiling Covered with Anti-static PVC Curtain (T=0.3mm)

-

M12 Foot Margin for stability and alignment

-

Anti-static PVC Strip Curtain Door

-

Control Box: Cold-rolled steel (powder-coated) or stainless steel

-

Cleanliness Range: Class 10 to 300,000 (ISO 14644-1 standard)

Why Cleanroom Filtration is Essential

-

Particle Control – HEPA/ULPA filters capture up to 99.99% of airborne contaminants

-

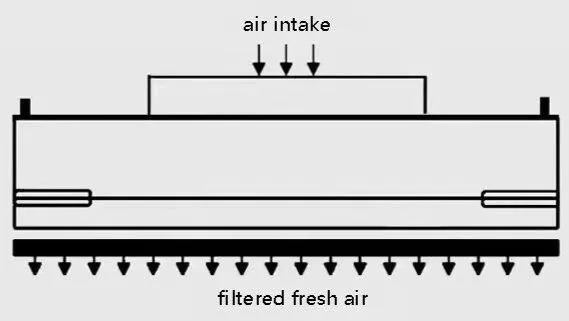

Uniform Airflow – FFUs provide consistent laminar airflow, minimizing turbulence

-

Localized Protection – Clean benches create sterile work zones for sensitive tasks

-

Regulatory Compliance – Designed to meet ISO and GMP cleanroom standards

Applications of Clean Benches & Filtration Systems

-

Pharmaceuticals – Protect sterile products during compounding and packaging

-

Semiconductors & Electronics – Prevent static and airborne contamination in microchip production

-

Medical Devices – Ensure sterile and controlled assembly environments

-

Biotechnology & Laboratories – Support sensitive experiments and R&D processes

Working Principle

Why Choose EEPS Engineering?

-

Local expertise in cleanroom design, construction, and maintenance across Malaysia

-

Customized cleanroom filtration solutions tailored to your industry needs

-

Full compliance with ISO 14644, GMP, and international cleanroom standards

-

Professional installation, testing, and reliable after-sales support