If you manage an industrial facility in Malaysia, watching your Tenaga Nasional Berhad (TNB) bill steadily climb has likely become a source of major frustration. You're not alone. While it's easy to blame rising tariffs, the true culprits are often hidden in plain sight within your own operations.

The reality is that an escalating electricity bill is more than just a cost issue; it's a clear symptom of operational inefficiency. The good news? This is a problem you can control. By understanding the root causes and implementing a strategic plan, you can transform this line item from a budgetary nightmare into a source of competitive advantage and improved profitability.

This comprehensive guide will first diagnose the key reasons your energy costs are increasing and then provide a detailed, actionable roadmap to regain control.

Part 1: Diagnosing the Problem – The 5 Major Culprits

A rising TNB bill is rarely due to a single fault. It's typically the result of several interconnected factors compounding over time.

1. Inefficient or Aging Equipment

The heart of your factory, the machinery. It is also the biggest energy consumer. Outdated or poorly maintained equipment is a silent energy thief.

-

Electric Motors: Accounting for up to 70% of a factory's industrial electricity use, motors that are old, undersized, or oversized operate far below their optimal efficiency. An inefficient motor converts valuable electricity into waste heat instead of mechanical power.

-

Air Compressors: Compressed air is one of the most expensive utilities in a plant. A single 3mm leak can cost you over RM 7,000 annually. Systems operating at incorrect pressures, with clogged filters, or without proper sequencing, waste immense amounts of energy.

-

Outdated Technology: Legacy machinery lacks the advanced power electronics and design efficiencies of modern equipment. This results in a higher energy draw for the same output, a cost that accumulates every single hour of operation.

2. The Hidden Tax: Poor Power Factor (PF)

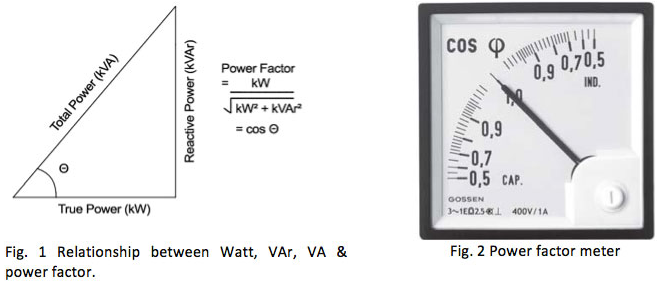

This is a technical but critical concept that directly impacts your bill. Power Factor measures how effectively your equipment uses the electrical power supplied.

-

The Issue: Inductive loads like motors, transformers, and welding machines cause a "lag" between the current and voltage. This creates "reactive power" (kVAR), which does no actual work but strains the electrical grid. A low Power Factor (below 0.85) means you are drawing more "apparent power" (kVA) than the "real power" (kW) you use.

-

The Penalty: To compensate for this inefficiency, TNB imposes a surcharge on your bill for a low Power Factor. You are literally being fined for wasting energy potential.

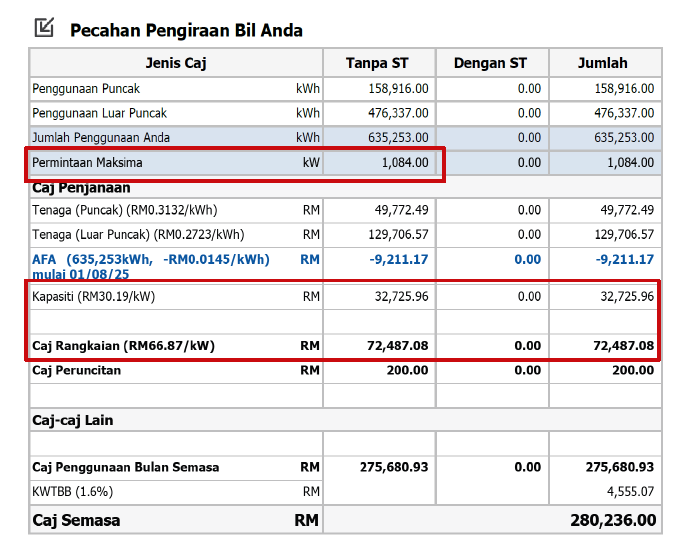

3. The Demand Spike Trap: Maximum Demand (MD) Charges

Industrial tariffs (C1, C2) have two main components, and MD is often the most misunderstood and costly.

-

What is MD? Maximum Demand is the highest average power (in kVA) your factory draws in any 30-minute period during the billing month. TNB must be prepared to supply this peak load at all times.

-

The Costly Spike: A single, short-term event—like starting several large machines simultaneously, can set a high MD for the entire month. This results in a significant fixed charge on your bill, regardless of your total energy consumption for the rest of the month.

4. Operational Blind Spots and Lack of Strategy

Treating electricity as a fixed, unmanageable cost is the first step towards waste.

-

No Sub-metering: With only one master meter for the entire facility, you have no visibility into which production line, machine, or shift is the primary energy consumer.

-

Poor Operational Practices: Leaving machinery idling during breaks, inadequate maintenance schedules, and poor production planning that creates simultaneous high-load activities all contribute to silent, consistent energy drain.

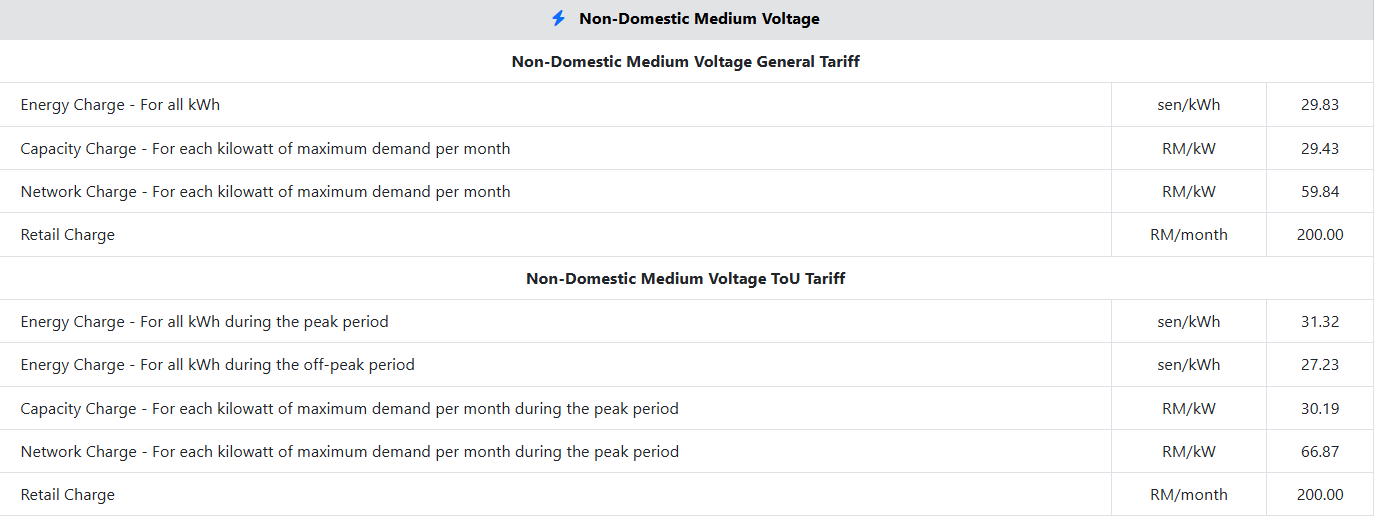

5. Time of Use (TOU) Tariff Mismanagement

Many industrial users are on a Time of Use tariff, where electricity costs vary by time of day.

-

Peak vs. Off-Peak: Energy is most expensive during peak hours (e.g., 2:00 pm - 10:00 pm on weekdays) and cheapest during off-peak hours (e.g., 10:00 pm - 2:00 pm). If your energy-intensive processes are scheduled during peak times, you are paying a premium for the same output.

.png)

Part 2: The Strategic Action Plan: From Quick Wins to High-Tech Solutions

Regaining control requires a phased approach, from foundational fixes to strategic technological investments.

Phase 1: The Foundation – Efficiency & Awareness

-

Conduct a Professional Energy Audit: This is the non-negotiable first step. A detailed audit will baseline your consumption, identify key waste areas, and provide a prioritized list of interventions with clear Return on Investment (ROI) calculations.

-

Implement Operational Excellence:

-

Launch a leak detection and repair program for your compressed air system.

-

Enforce a strict preventative maintenance schedule for motors, pumps, and HVAC systems. Clean equipment uses less energy.

-

Cultivate an energy-conscious culture: Mandate shutting down equipment and lighting when not in use.

-

Phase 2: The Upgrade – Retrofits and Corrections

-

Invest in High-Efficiency Hardware:

-

Upgrade to IE3/IE4 Class Motors: These high-efficiency models can save 2-8% in energy.

-

Retrofit with Variable Speed Drives (VSDs): Installing VSDs on motors for pumps, fans, and compressors allows them to run at the speed required by the load, not just at full blast. Savings can be 20-50%.

-

Switch to LED Lighting: A straightforward retrofit that can cut lighting energy consumption by over 50% and reduce cooling load due to lower heat output.

-

-

Install Automatic Power Factor Correction (APFC) Units: These devices automatically counteract the reactive power in your system, bringing your Power Factor above 0.95 and eliminating the TNB surcharge.

Phase 3: The Mastery – Advanced Management and Storage

-

Deploy an Integrated Energy Management System (EMS) and Battery Storage (BESS): This is the pinnacle of modern energy cost control, directly tackling TOU and MD charges.

-

The Brain: Energy Management System (EMS) This sophisticated software is your command centre. It monitors real-time energy consumption, grid electricity prices (TOU), and the status of your battery system.

-

The Muscle: Battery Energy Storage System (BESS) This is a large-scale battery installed on your site.

How They Work Together for Maximum Savings:

-

Maximum Demand (MD) Peak Shaving: When the EMS detects your total power draw is approaching your MD limit, it instantly dispatches power from the BESS to "shave" the peak. This prevents costly spikes and protects you from high MD charges for the month.

-

Time of Use (TOU) Energy Arbitrage: The EMS intelligently charges the BESS during cheap off-peak hours. Then, during expensive peak hours, it powers your facility from the stored battery energy, drastically reducing your kWh energy charge.

-

Additional Benefits: This combination also provides enhanced power resilience against brief outages and future-proofs your facility for potential grid services.

.png)

-

Conclusion: Turn Your Energy Bill into a Strategic Asset

Your factory's TNB bill should not be a variable, unpredictable cost. By moving from a reactive to a proactive energy management strategy, you can lock in significant savings, improve your operational efficiency, and boost your bottom line.

The journey begins with understanding and measurement, moves through targeted upgrades, and can culminate in the intelligent, automated optimization provided by an EMS and BESS. Every ringgit saved on energy is a ringgit that goes directly to your profit.

Ready to Stop Guessing and Start Saving?

Our team of energy specialists is ready to help you diagnose your specific challenges and build a tailored roadmap to energy efficiency. From initial audits to implementing cutting-edge BESS and EMS solutions, we provide end-to-end support.

[Contact us today for a complimentary, no-obligation facility energy assessment.] Let's work together to take control of your costs.

BR 15042

BR 15042  VN 5413

VN 5413  US 5269

US 5269  IN 3199

IN 3199  AR 2392

AR 2392  MX 2279

MX 2279  MY 1768

MY 1768  CN 1635

CN 1635