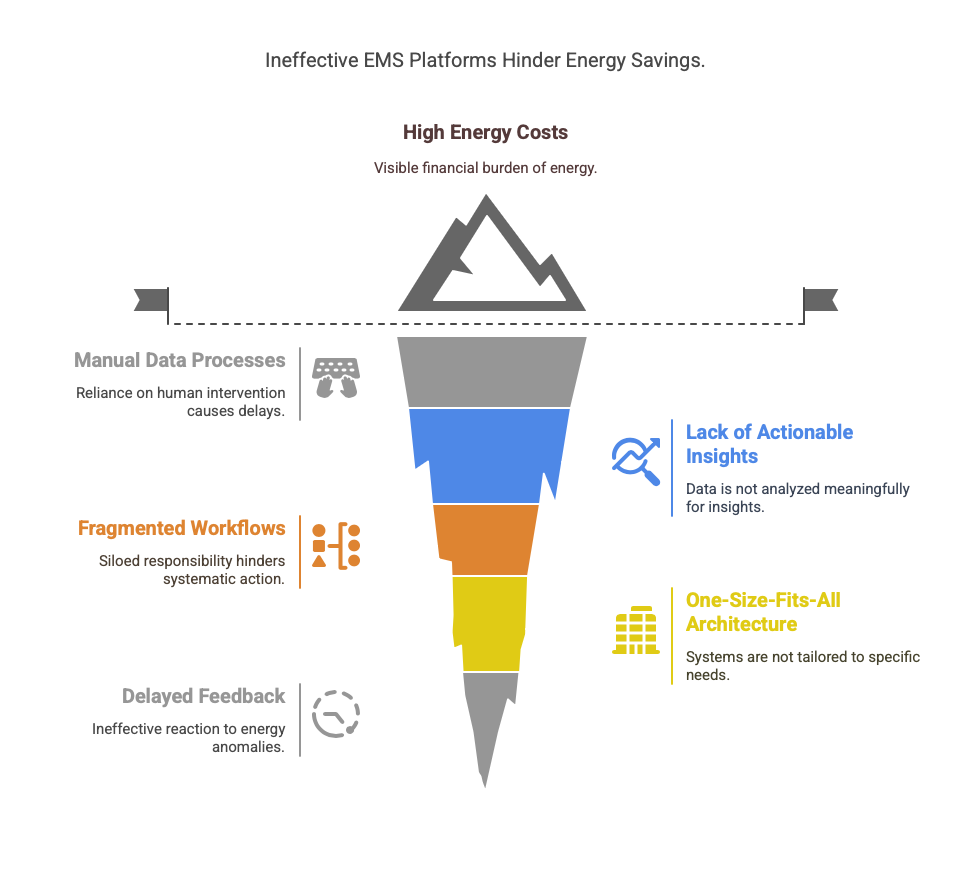

In today’s landscape, where energy efficiency isn’t just about cost savings but also about meeting sustainability goals, many organizations have adopted Energy Management Systems (EMS) with high hopes. Yet despite substantial investment, many of these systems quietly fade into the background—underutilized, underperforming, and sometimes even abandoned. Why does this happen?

It’s not because energy management doesn’t matter—it does. The problem lies in how traditional EMS platforms are built and operated. Here’s a closer look at the common pitfalls that cause traditional EMS deployments to fall short, and what can be done to address them:

1. Too Much Manual Work, Not Enough Momentum

Most conventional EMS platforms still require technicians to manually collect data, fill out spreadsheets, and reconcile readings with SCADA systems. This kind of process is not only time-consuming, but also prone to delays and errors. It slows things down and makes energy management feel like a chore.

Eventually, teams push energy reporting to the sidelines, and the system becomes more of a data archive than a dynamic tool for savings.

2. Data Without Meaning

Yes, EMS platforms gather data—but they often fall short of turning that data into something useful. Charts and raw figures don’t tell a story unless they're backed by intelligent insights. Without built-in analytics or anomaly detection, critical energy inefficiencies go unnoticed until it’s too late. This turns dashboards into clutter instead of clarity.

3. Disconnected Teams, Disconnected Results

Energy-saving isn’t just one department’s job—it’s a shared responsibility. But traditional EMS systems often exist in silos, disconnected from the people who could actually fix the issues they reveal. Without integration into workflow or ticketing tools, problems go unresolved, and opportunities slip through the cracks.

To make things worse, organizations often need external consultants to run assessments or make configuration changes, leading to delays and higher costs.

4. Generic Systems Don’t Fit All

Whether you're operating a data center, manufacturing plant, or office building, your energy patterns are unique. Traditional EMS tools tend to apply the same approach everywhere, without adapting to industry-specific needs. That results in reports and alerts that miss the mark—too broad to be useful, and too vague to be trusted.

5. No Real-Time Response, Only Hindsight

Most EMS platforms operate in the past—offering reports days or weeks after energy events have occurred. By then, it's often too late to react. Without real-time monitoring or predictive alerts, teams are always playing catch-up, and energy losses pile up before anyone notices.

6. High Costs, Unclear Returns

EMS deployments can be expensive—software, hardware, consultants, training—and if they don’t deliver measurable savings or lasting usage, they quickly lose executive support. This leads to stagnation, halted funding, and missed opportunities for innovation.

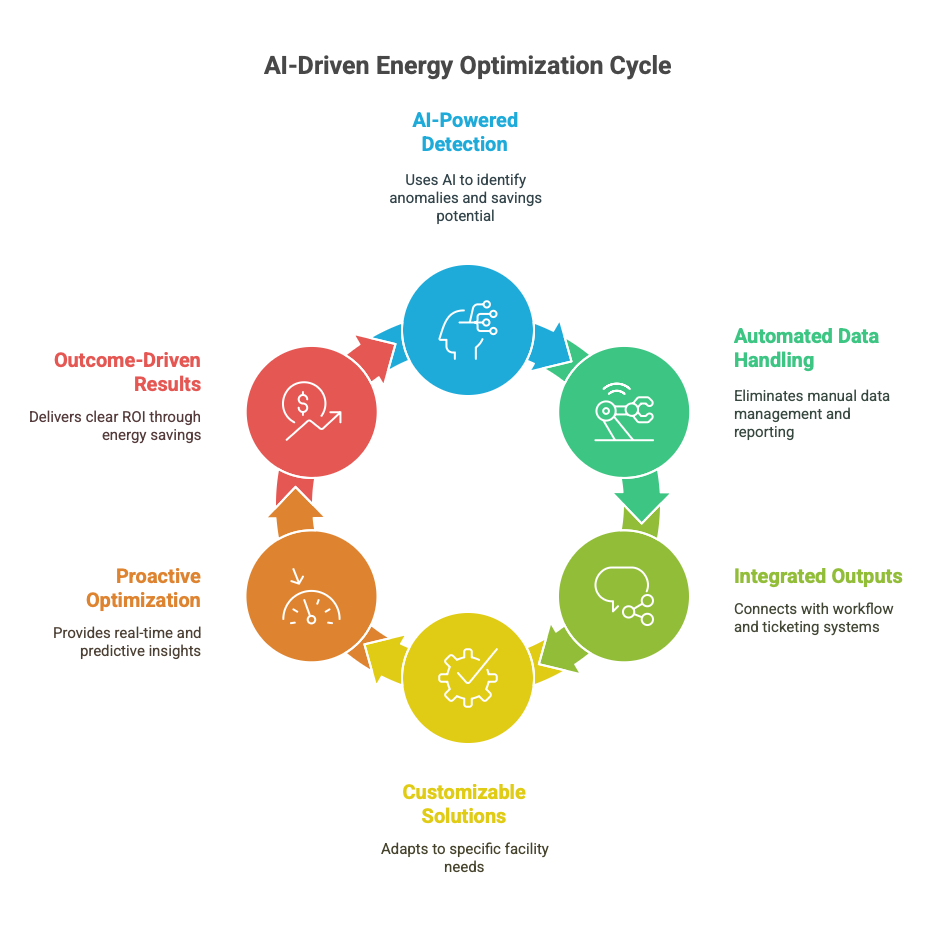

The Path Forward: Smarter, Integrated, Real-Time EMS

To avoid the common traps of traditional EMS, future-ready systems must be built differently. Here’s what they need to deliver:

- AI-powered analytics that can detect anomalies and uncover savings opportunities automatically.

- Automated data collection and reporting that eliminate repetitive manual tasks.

- Integrated workflows and ticketing that ensure insights are acted on, not ignored.

- Customizable dashboards and KPIs tailored to specific industries and sites.

- Real-time optimization and predictive alerts for faster decision-making.

- Clear ROI frameworks tied directly to energy savings and emissions reduction.

An EMS should be more than a box-ticking exercise—it should be a living, intelligent system that supports operations in real time. If your current EMS feels more like a burden than a benefit, it’s time to consider smarter solutions designed for today’s challenges and tomorrow’s

If your current EMS feels more like a burden than a benefit, it may be time to rethink the architecture—and invest in solutions designed for the future of industrial and commercial energy intelligence.