Optimizing Industrial Maintenance with Scantech 3D Scanning Technology

by Obsnap Penang

In today’s highly competitive industrial landscape, minimizing equipment downtime and ensuring reliable maintenance procedures are critical to operational success. Traditional methods of equipment inspection and part replacement often involve time-consuming manual measurements, dismantling processes, and the lack of original part documentation — leading to extended downtimes and increased costs.

At Obsnap Penang, we proudly offer Scantech’s advanced 3D scanning solutions — a cutting-edge approach to equipment maintenance that prioritizes efficiency, accuracy, and on-site adaptability.

The Role of 3D Scanning in Modern Maintenance Workflows

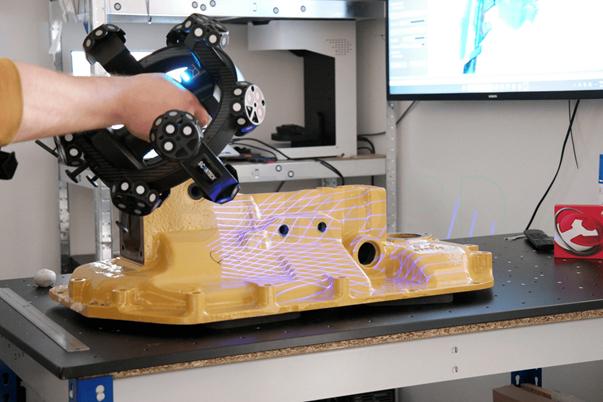

Scantech’s 3D scanning systems are engineered to deliver rapid, high-resolution data acquisition, enabling precise inspection and reverse engineering of worn, damaged, or undocumented components. These systems have become a critical tool for industries such as petrochemical, marine, aerospace, power generation, and heavy machinery, where equipment complexity and high downtime costs demand smart solutions.

Key Advantages of Scantech 3D Scanning in Maintenance

Instantly generate accurate 3D data of existing parts for CAD modeling, redesign, or replication — ideal for legacy or non-standard components.

- Non-Destructive and Non-Contact Inspection

Avoid dismantling entire systems. Capture surface geometry and critical measurements without affecting the part’s integrity.

- High Accuracy, Even in Harsh Environments

Scantech’s scanners are optimized for real-world industrial conditions, ensuring reliability and precision even in challenging environments.

- Improved Efficiency and Reduced Downtime

Streamline maintenance cycles by reducing manual tasks, accelerating repair timelines, and increasing diagnostic accuracy.

- Cost Reduction

Eliminate the need for trial-and-error rework and reduce reliance on external measurement services or part suppliers.

Proven Performance Across Industrial Sectors

Many global companies are already integrating Scantech 3D scanning into their maintenance and quality assurance workflows. Applications include:

- Reverse engineering of broken pump impellers and turbine blades

- Dimensional validation of pipe flanges and complex fittings

- Wear analysis and deformation tracking on heavy components

- Design restoration of outdated machinery with no CAD files

These digital solutions help industries make data-driven decisions, ensuring that repairs and replacements meet exacting technical requirements.

Partner with Obsnap Penang for Advanced Maintenance Solutions

As an authorized Scantech distributor, Obsnap Penang is committed to helping businesses across Malaysia adopt smart 3D scanning technologies to enhance their maintenance and inspection capabilities.

Our team offers full support — from product consultation and on-site demonstration to after-sales service and technical training.

CONTACT US FOR MORE DETAILS: