Depropanizer

Level measurement and point level detection in the depropanizer

Process data

Application

Your benefit

Recommended products

VEGAFLEX 86

Level measurement with guided wave radar in the depropanizer

- Non-moving parts are immune to mechanical failure

- Low maintenance requirements reduce downtime and costs

- Certain measurement even by changing process conditions

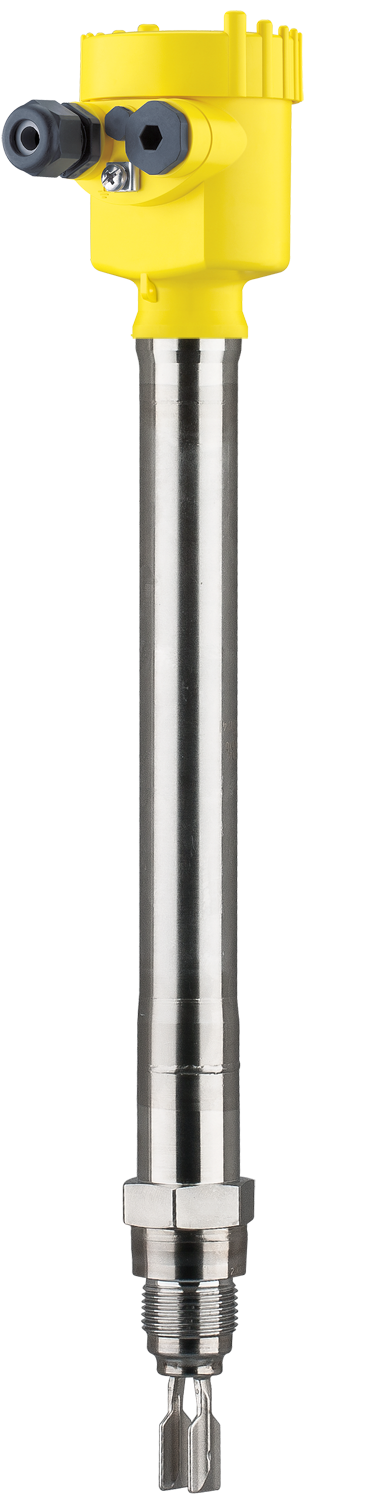

VEGASWING 66

Vibrating level switch for monitoring high and low alarm in the depropanizer

- Reliable measurement unaffected by high temperature and pressure

- Test function during operation provides higher plant availability

- Redundancy increases plant safety and availability