Please login to use this feature.

You can use this feature to add the product to your favourite list.

Close

You have removed this product from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your favourites list.

Close

This company has been removed from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your inquiry cart.

Close

This company has been added to your inquiry cart.

Close

This company has been removed from your inquiry cart.

Close

This product has been added to your inquiry cart.

Close

This product has been removed from your inquiry cart.

Close

Maximum number of Product/Company has been reached in inquiry cart.

Close

You have removed this product from your favourite list.

Close

Daily Login Reward

Congratulations!

You��ve earned your daily login reward for today!

5 NP PointHere are the reward you��ve earned!

Check your Daily Login Rewards

Be sure to come back everyday for more rewards!

Thanks!

Scan and Whatsapp Me

![qr code]() Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Waktu

Pejabat

Isnin - Jumaat 9:00 AM - 5:00 AM

Sabtu - Ahad Closed

We′re closed on

Public Holiday

Get the latest

VG Instruments (SEA) Sdn Bhd

App for Android

Open

Closed

Selangor,Kuala Lumpur (KL),Kepong - Level measurement and point level detection of catalyst

10-Dec-2018

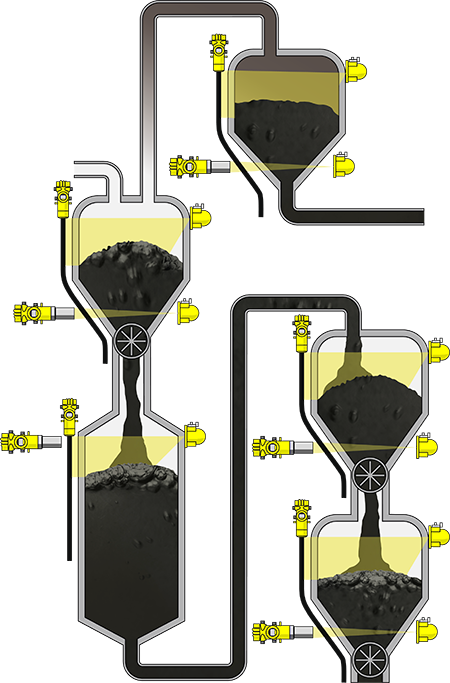

Continuous catalyst regeneration

Level measurement and point level detection of catalyst

Process data

Measuring task

Level measurement and point level detection

Measuring point

Vertical column

Measuring range up to

20 m

Medium

Liquid distillate naphtha

Process temperature

+230 … +400 °C

Process pressure

+20 … +60 bar

Special challenges

High process temperature

Application

Platformers and reformers, both catalyst-based processes, require “fresh” catalyst at a given point in their cycle. To provide fresh catalyst without shutting down the process, a continuous catalyst regeneration unit can be installed. This unit regenerates the spent catalyst so that it can be used again. Maintaining the proper level in the vessel ensures that the expensive catalyst is used at the highest level of efficiency without waste.

Your benefit

Reliable

Non-invasive measurement ensures high plant availability

Cost effective

Lightweight design reduces mounting costs

User friendly

External mounting does not interrupt the process

Recommended products

POINTRAC 31

Radiation-based sensor used as point level switch for catalyst regeneration reactor measurement

- Thanks to lightweight sensor design, no special mounting equipment is required

- Compact and lightweight detector mounts easily

- Secure and reliable level measurement thanks to non-contact measuring technique, ideal for all process conditions

Measuring range - Distance

FIBERTRAC 31

Radiation-based sensor for continuous level measurement

- Simple function test during operation reduces down time and resulting costs

- Secure and reliable level measurement thanks to non-contact measuring method

- Long detector length up to 7 m minimizes the need for additional platform construction

Measuring range - Distance

Hantar mesej anda ke VG Instruments (SEA) Sdn Bhd