Please login to use this feature.

You can use this feature to add the product to your favourite list.

Close

You have removed this product from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your favourites list.

Close

This company has been removed from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your inquiry cart.

Close

This company has been added to your inquiry cart.

Close

This company has been removed from your inquiry cart.

Close

This product has been added to your inquiry cart.

Close

This product has been removed from your inquiry cart.

Close

Maximum number of Product/Company has been reached in inquiry cart.

Close

You have removed this product from your favourite list.

Close

Daily Login Reward

Congratulations!

You��ve earned your daily login reward for today!

5 NP PointHere are the reward you��ve earned!

Check your Daily Login Rewards

Be sure to come back everyday for more rewards!

Thanks!

Scan and Whatsapp Me

![qr code]() Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Waktu

Pejabat

Isnin - Jumaat 9:00 AM - 5:00 AM

Sabtu - Ahad Closed

We′re closed on

Public Holiday

Get the latest

VG Instruments (SEA) Sdn Bhd

App for Android

Open

Closed

Selangor - Level, switching and pressure measurement in the conversion process for alcohol production

06-Dec-2018

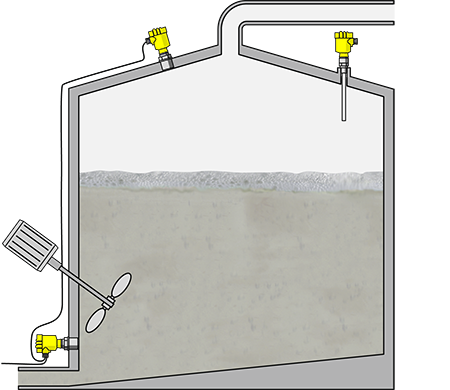

Fermentation in the ethanol plant

Level, switching and pressure measurement in the conversion process for alcohol production

Process data

Measuring task

Pressure and level measurement, point level detection

Measuring range up to

5 m

Process temperature

+20 … +40 °C

Process pressure

0 … 5 mbar

Features

Fluctuating gauge pressure, foaming

Application

The heart of the ethanol plant is the fermentation process. This is where the sugars in the mash are converted into alcohol, which, in the subsequent distillation process, is then concentrated to a strength of 99.9 %. The CO2 gas given off by the fermentation is captured and used for carbonation in the beverage industry. To keep the fermenter vessel operating in its optimal range, reliable monitoring of the process parameters including the vessel level and overall pressure is required.

Your benefit

Reliable

Accurate readings under all process conditions in the fermenter

Cost effective

Level and pressure measurement using electronic differential pressure provides all relevant measurement data

User friendly

Simple mounting and setup

Recommended products

VEGABAR 82

Measurement of the level and gauge pressure during mash fermentation with electronic differential pressure

- High abrasion resistance thanks to ceramic materials

- Different measuring cells enable application oriented selection

- Easy cleaning thanks to front-flush measuring cells

Measuring range - Distance

Measuring range - Pressure

VEGACAP 64

Capacitive point level detection of the mash in the fermentation process

- Reliable foam detection, regardless of consistency

- Unaffected by buildup, even with product deposits and thick foam

- Adjustment-free setup and commissioning minimizes costs

Hantar mesej anda ke VG Instruments (SEA) Sdn Bhd

BR 28462

BR 28462  US 14282

US 14282  VN 4469

VN 4469  IN 4120

IN 4120  MX 3236

MX 3236  AR 2576

AR 2576  AO 2518

AO 2518  GB 1938

GB 1938