Please login to use this feature.

You can use this feature to add the product to your favourite list.

Close

You have removed this product from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your favourites list.

Close

This company has been removed from your favourite list.

Close

Please login to use this feature.

You can use this feature to add the company to your inquiry cart.

Close

This company has been added to your inquiry cart.

Close

This company has been removed from your inquiry cart.

Close

This product has been added to your inquiry cart.

Close

This product has been removed from your inquiry cart.

Close

Maximum number of Product/Company has been reached in inquiry cart.

Close

You have removed this product from your favourite list.

Close

Daily Login Reward

Congratulations!

You��ve earned your daily login reward for today!

5 NP PointHere are the reward you��ve earned!

Check your Daily Login Rewards

Be sure to come back everyday for more rewards!

Thanks!

Scan and Whatsapp Me

![qr code]() Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Note: Some mobile phone default QR scanners cannot scan to open the WhatsApp App directly.

Cancel

Waktu

Pejabat

Isnin - Jumaat 9:00 AM - 5:00 AM

Sabtu - Ahad Closed

We′re closed on

Public Holiday

Get the latest

VG Instruments (SEA) Sdn Bhd

App for Android

Open

Closed

Selangor,Kuala Lumpur (KL),Kepong - Pengedar Level measurement in the compressor knockout drum

10-Dec-2018

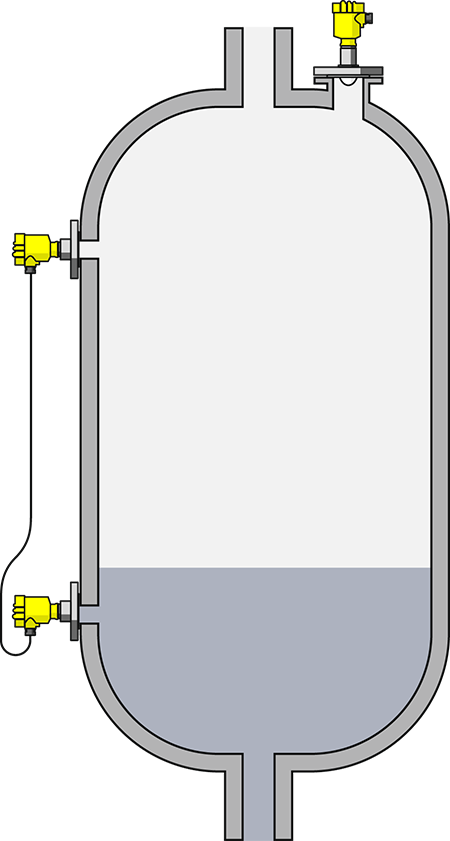

Compressor knockout drum

Level measurement in the compressor knockout drum

Process data

Measuring task

Level measurement

Measuring range up to

2 m

Medium

Hydrocarbon or water

Process temperature

+60 … +120 °C

Process pressure

+3 … +10 bar

Special challenges

Changing medium properties

Application

The vapour liquid separation that occurs in a knockout drum protects the waste or cooling stream from process vapours and compressors from water. This crucial measurement point means it requires constant, reliable level monitoring without being influenced by the high volume of vapour inside the vessel. A reliable instrument ensures that there is no water carry-over into the compressor, avoiding the extremely expensive downtime that results from an upset.

Your benefit

Reliable

Diverse technologies with comparative output can provide redundant level measurement

Cost effective

Materials with high chemical resistance reduce maintenance costs

User friendly

Easy installation and setup

Recommended products

VEGAPULS 64

Level measurement with radar in the compressor knockout drum

- Reliable measurement, unaffected by vapour presence

- Easy installation directly in the drum

- Unaffected by changing density

Measuring range - Distance

VEGABAR 82

Electronic differential pressure system for measurement redundancy in the compressor knockout drum

- No additional temperature influences because no liquid capillary connection required

- Very good reproducibility and long-term stability

- High resistance diaphragm materials

- Easy installation because no insulation for capillary needed

Measuring range - Distance

Measuring range - Pressure

Hantar mesej anda ke VG Instruments (SEA) Sdn Bhd

US 8316

US 8316  GB 6323

GB 6323  CA 5562

CA 5562  AU 5238

AU 5238  IE 4359

IE 4359  NZ 2035

NZ 2035  BR 1178

BR 1178  SG 494

SG 494