Sliding vane design is ideal for, LPG, butane, propane, freon, fuel, gasoline, DME, anhydrous ammonia, propellants, refrigerants and similar liquefied gases.

Utilizing unique sliding vane design, these positive displacement pumps offer the best combined characteristics of sustained high level performance, energy efficiency, trouble-free operation and low maintenance cost.

Pump models are available in 1.5" to 4" port sizes. All models have ductile iron construction for thermal shock resistance, low friction ball bearings for high efficiency and quiet operation.

|

|

Max. Capacity: 65 m3/h | |

|

|

Max. Diffr. Pressure: 8.5 bar | |

|

|

Max. Viscosity: 100 cSt | |

|

|

Temperature Range: -30 0C to +150 0C |

Features

- Application variety with 8 different casing size

- They require less horsepower than other positive displacement pumps. So you spend less on motors initially and less on electricity to operate the pumps after they are installed

- High capacity at lower speeds. These lower operating speeds mean quiter operation, longer service life and reduced maintenance requirements.

- Can be used same pump for filling and discharge with both direction properties

- Self-adjusting vanes keep performance high

- Vane replacement in easy inspection and no special tools require

- Replaceable casing liner and end disc

- Advanced polymer

- Internal relief valve

- Self-priming

- Cavitation sppression liner

- The design allows only mechanica seal (Dual).

- Dual-Ended shaft allows for both direction

- These vane pumps can be coupling with V-Belt, Hydro motor or Gearbox

- Connection type options are ANSI & DIN Flange or BSP&NPT threaded connection

Options

- These vane pumps can be coupling with V-Belt, Hydro motor or Gearbox

- Connection type options are ANSI & DIN Flange or BSP&NPT threaded connection

- V-Belt coupling mostly used for truck application to less space

- Hydromotor coupling is mostly used where the no electric.

Documents

Working Principle

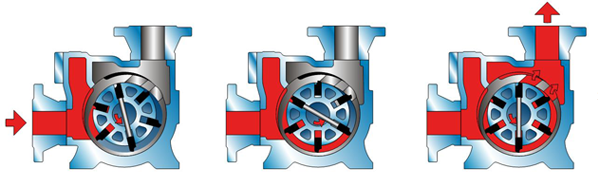

As shown in Figueres, the pumps use a rotor with sliding vanes that draw the liquid in behind each vane, through the inlet port and into the pumping chamber. As the rotor turns, the liquid is transferred between the vanes to the outlet where it is discharged as the pumping chamber is squeezed down. Each vane provides a positive mechanical push to the liquid before it.

Vane contact with the chamber wall is maintained by three forces:

- Centrifugal force from the rotors rotation

- Push rods moving between opposing pairs of vanes

- Liquid pressure entering through the vane grooves and acting on the rear of the vanes

US 7466

US 7466  GB 7337

GB 7337  AU 6778

AU 6778  CA 6748

CA 6748  IE 4132

IE 4132  NZ 3052

NZ 3052  BR 874

BR 874  CN 843

CN 843