Dual partial-discharge detector with high noise resistance for EV motors

Why is partial discharge testing of motor windings necessary?

Deep inside the motor winding a tiny discharge appears, unseen but real. Each surge pulse fuels the damage, eroding the insulation from within. Cracks, carbonization…what begins as a faint spark can end in breakdown — or fire.

Insulation resistance and hipot tests? They find what’s already failed. Partial discharge starts long before silent, cumulative, irreversible.

Partial discharge testing reveals what others can’t see early degradation, hidden defects, the beginning of failure. Reliability starts before the fault.

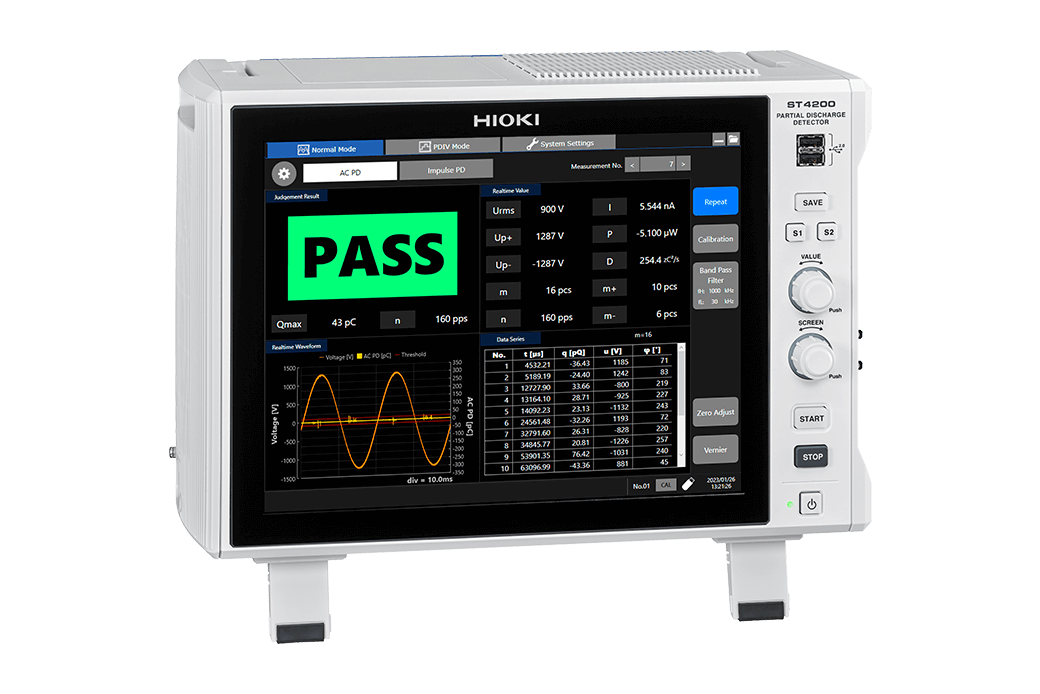

The Hioki ST4200-50 delivers stable, reproducible measurements even in noisy production lines. Detect. Protect. Trust. Hioki — visualizing the hidden destruction.

Noise-Resistant PD Testing for Enhanced Motor Quality

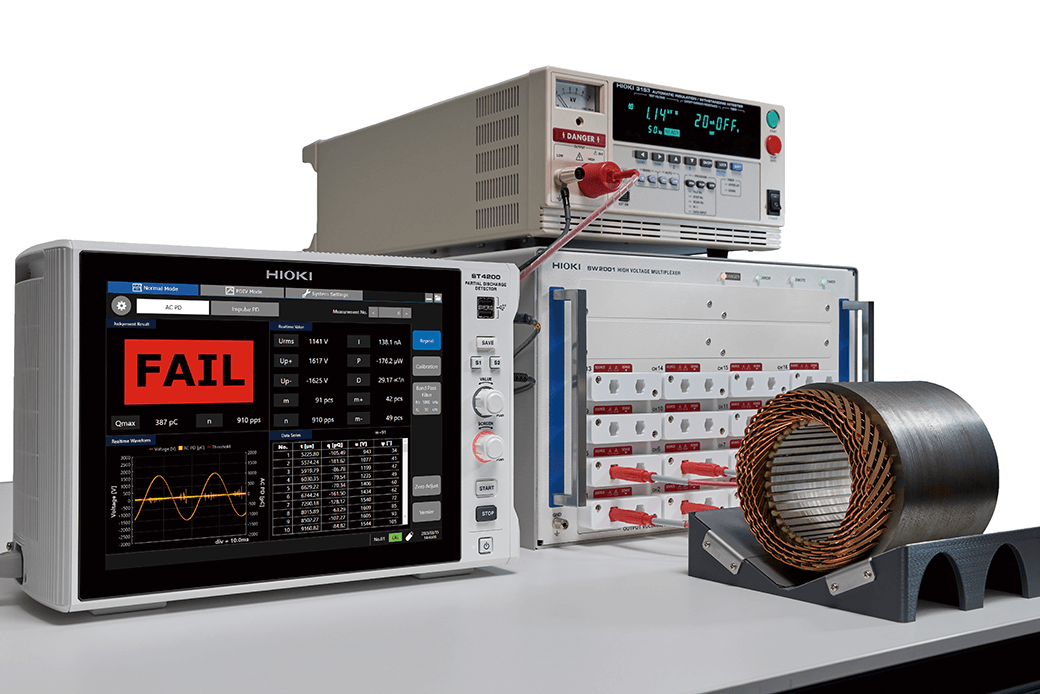

The ST4200-50 Partial Discharge Detector offers comprehensive partial discharge (PD) detection. It also enables seamless system integration for motor production testing when paired with the SW2001 High Voltage Multiplexer. Furthermore, the ST4200-50's PD detection uses high-frequency CTs which mitigate noise interference common to production lines. Such noise on production lines make PD detection using a microwave antenna often difficult, and at times, nearly impossible.

Key Features

- Compatible with the SW2001 High Voltage Multiplexer

- Noise-resistance through high-frequency CT

- AC and Surge dual-mode partial discharge detection

Model No. (Order Code)

| ST4200-50 | |

|---|---|

| AC Partial Discharge Test Kit | ST4200-50, ST9210, 3153, L2270, L2271, L2265, L2266, L9218 (x2), L9637 |

| Surge Partial Discharge Test Kit | ST4200-50, ST4030A, surge PD sensor set |

| AC/Surge Partial Discharge Test Kit | ST4200-50, ST9210, ST4030A, 3153, L2270, L2271, L2265, L2266, L9218 (x2), L9637, surge PD sensor set |

Maximize the detection of latent failures

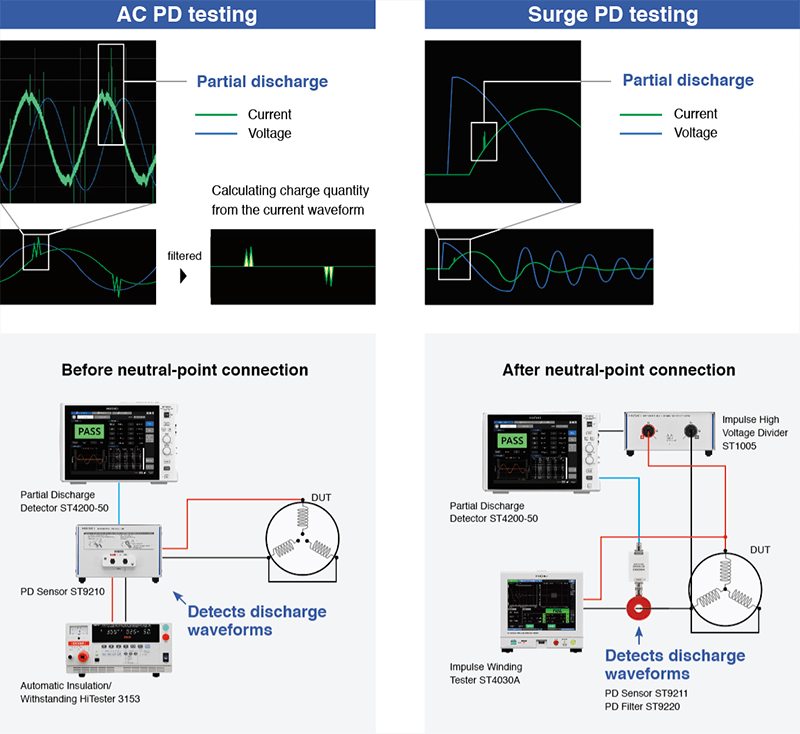

Dual-mode PD detection

Discover latent insulation defects in motor windings with the AC PD test (IEC 60270 and IEC 60034-27-1 compliant) and surge PD test (IEC 61934 Ed. 2 and IEC60034-27-5 compliant). The ability to select between the two types of PD tests allows you to customize your inspection process to the specific needs of each motor, maximizing the detection of latent failures.

Reliable PD testing even on the production line

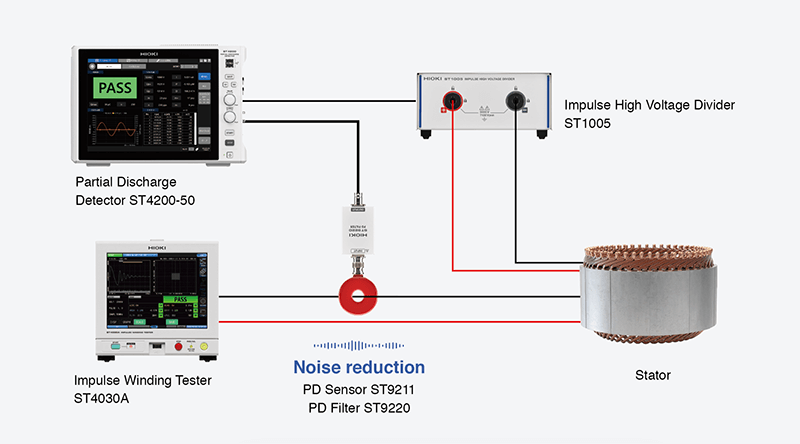

Noise-resistant PD detection with a high-frequency CT

Partial discharge testing on production lines with a microwave antenna is highly susceptible to noise interference. Using a high-frequency CT minimizes noise, simplifies installation by reducing the need for precise positioning, and thus prevents measurement errors.

Simplified system design for reduced noise impact

Integration with the SW2001 High Voltage Multiplexer

Complex testing environments often come with high noise which are difficult to reduce. The ST4200-50 Partial Discharge Detector's high noise resistance can be further minimized by integrating with the SW2001's multiplexer-based architecture. This design significantly reduces wiring complexity by consolidating multiple input signals, minimizing cable runs and interconnections. This approach effectively reduces potential noise sources such as electromagnetic interference (EMI), ground loops, and capacitive coupling, resulting in more accurate and reliable measurements.

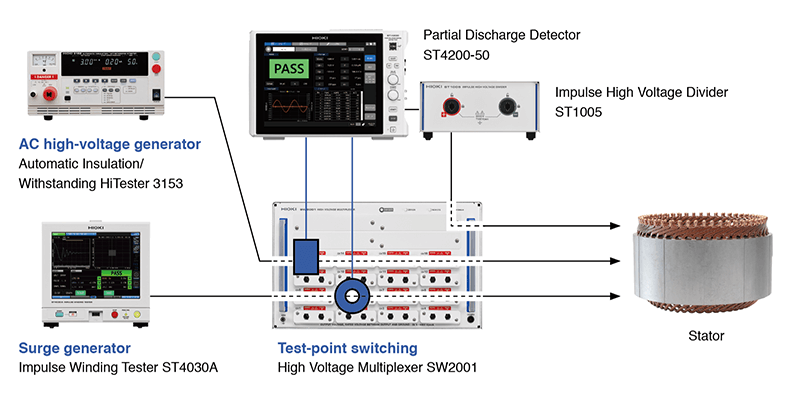

Basic setup for partial discharge testing:

- 1. Partial Discharge Detector ST4200-50

- 2. Automatic Insulation/Withstanding HiTester 3153 as an AC high-voltage power supply

- 3. Impulse Winding Tester ST4030A as an Impulse power supply

- 4. High Voltage Multiplexer SW2001 for switching between test points

- 5. Partial discharge sensor for AC PD testing *1

- 6. Partial discharge sensor for surge PD testing *1

- *1:These sensors are built into the SW2001. Please specify at time of order as the component is embedded during the manufacturing process.

BR 17671

BR 17671  VN 11056

VN 11056  MY 5704

MY 5704  US 5505

US 5505  IQ 4435

IQ 4435  BD 4426

BD 4426  CN 3172

CN 3172  IN 3100

IN 3100