In the dairy processing industry of Southeast Asia, standardized automation machines have been introduced in the production and packaging due to sanitary and hygiene concerns. However, in the final step, most plants still rely on laborers to stack the products onto the pallets. The Leantec team decided to accept the request from a renowned dairy processing factory to introduce palletizing robots with sensors and customized grippers to accomplish whole-factory automation.

Originally, at least 2 to 3 people were needed for the entire palletizing process in each of the production lines (1 or 2 people for the box stacking, 2 others to change the trays). However, the speed of the production line requires one completed box every six seconds on average. The palletizing process would drag due to understaffing or the inability to change the trays quickly enough, affecting the production rate of the entire production line. The introduction of the robotic arms is perfect for enhancing the production efficiency, also allowing the production to always continue without any downtimes.

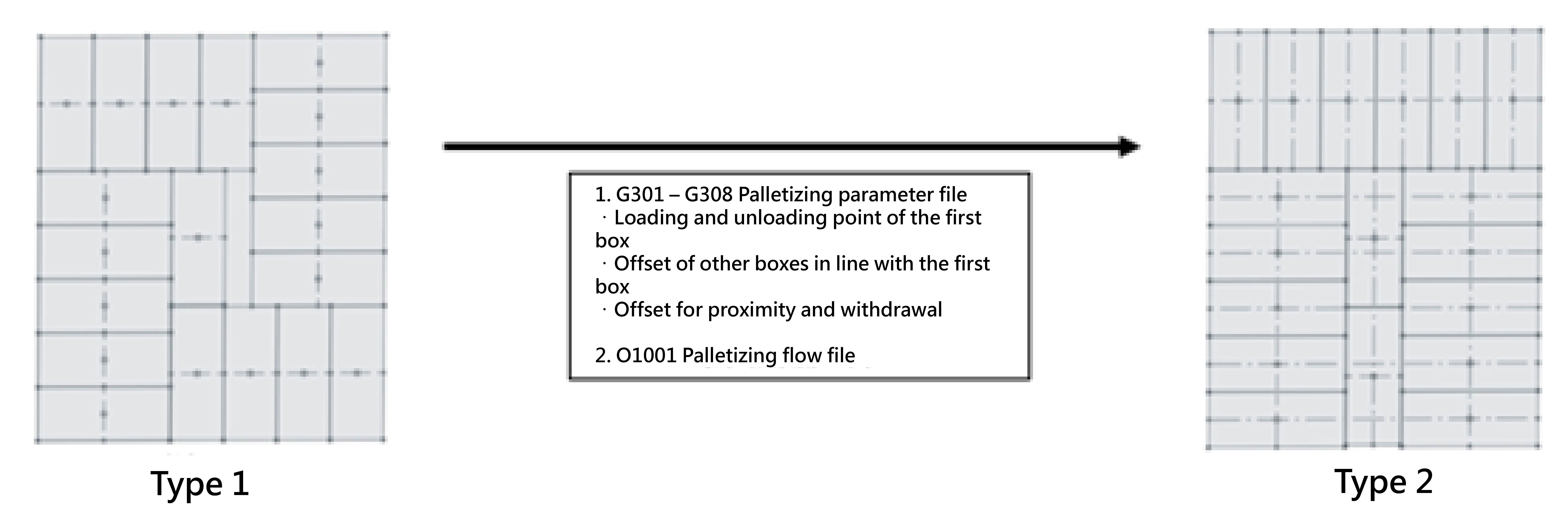

In this case, the Leantec team integrated software and hardware for the solution. First, the palletizing parameter files and the palletizing program developed by Syntec were integrated into a palletizing software package, which can be replicated and applied to any items that needed palletizing with minimal changes. The robots are also in line with the program flow and requirements, enabling the adjustment for arm movements. With the integration of the grippers and the sensors, all needs of the manufacturer have been met.

With the highly flexible robotic arms, reproducible workability, and easy programming, the introduction of Leantec robots immediately increased the efficiency of the overall equipment, succeed in replacing redundant equipment and workers, and further simplified and reduced the layout space required for the plant. Also, the robots can operate through the standard-setting while utilizing its sensors, enhancing the safety of the plant even further. In the future, it shall also be successfully applied in the fields of packaging and food production with little effort.

BR 11868

BR 11868  US 7749

US 7749  IN 3866

IN 3866  VN 2629

VN 2629  MY 2040

MY 2040  AR 2025

AR 2025  SG 1685

SG 1685  GB 1614

GB 1614