A valve manufacturer specializes in the research and development and production of valve parts; the valve in this case is used in the fire protection system of a bank, which requires high stability and consistency. Through the optimization of the manufacturing process and the the automatic production system, the stability of the production capacity is guaranteed.

��Customer's requirement

�� The automatic unit realizes automatic loading and unloading production without stopping

�� Cooperate with 3 indexing chuck CNC lathes and 1 drilling machine to realize one-to-four processing

�� The tooling and gripper jaws realize precise positioning and the function of unloading in-position detection

���ⷽ��

�� U-shaped configuration

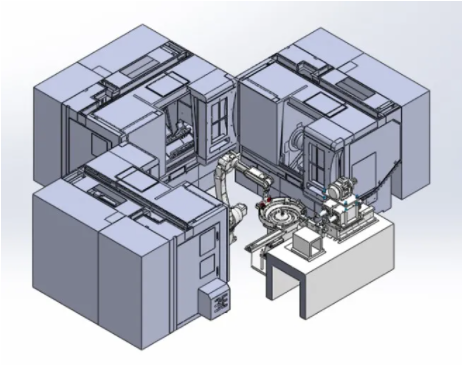

-3 lathes are placed in U-shape, the silo and the drilling machine are placed in front, and the manual maintenance aisle is reserved at the same time

�� Prise pickup

-The robot with 10KG payload and max reach of 1598mm cooperates with a vibrating plate for loading and unloading

-The robot adopts three fingers and two gripper jaws to realize instant switching between blanks and finished products

-High-precision sensors are added to the end of the robot to detect the placement of parts

�� Quick response of machine and robot

-Machine tool adopts SYNTEC 6TA system, and uses the high-precision spindle positioning function to realize the angle positioning of the indexing chuck.

-Machine tools and robots can communicate quickly via SYNTEC's NetPLC function

-Abnormal detection and alarm function to ensure the stability of processing

�� Cloud monitoring

-Cooperate with SYNTEC cloud monitoring to realize workshop dashboard and lean production management

��Advantage

�� One-stop solution for intelligent processing��LEANTEC RobotCells support pick and place, inspection, tool compensation and cloud system.

�� Increase efficency and lower costs��Realize the goal of one-time investment, one-year return, and life-long useage.

�� Safe and reliable��With safety detection and protection mechanism to avoid potential safety hazards.

After the introduction of the automatic production, manpower is reduced, and one person per shift is reduced by one set of automatic units. The addition of the robot arm avoids the unstable processing caused by the clamping deviation, improves the stability of the product, and realizes 24-hour non-stop production, which helps move toward lean production.

BR 17142

BR 17142  VN 4581

VN 4581  US 4366

US 4366  IN 2826

IN 2826  AR 2631

AR 2631  CN 2391

CN 2391  MX 1721

MX 1721  BD 1370

BD 1370